Wafer components

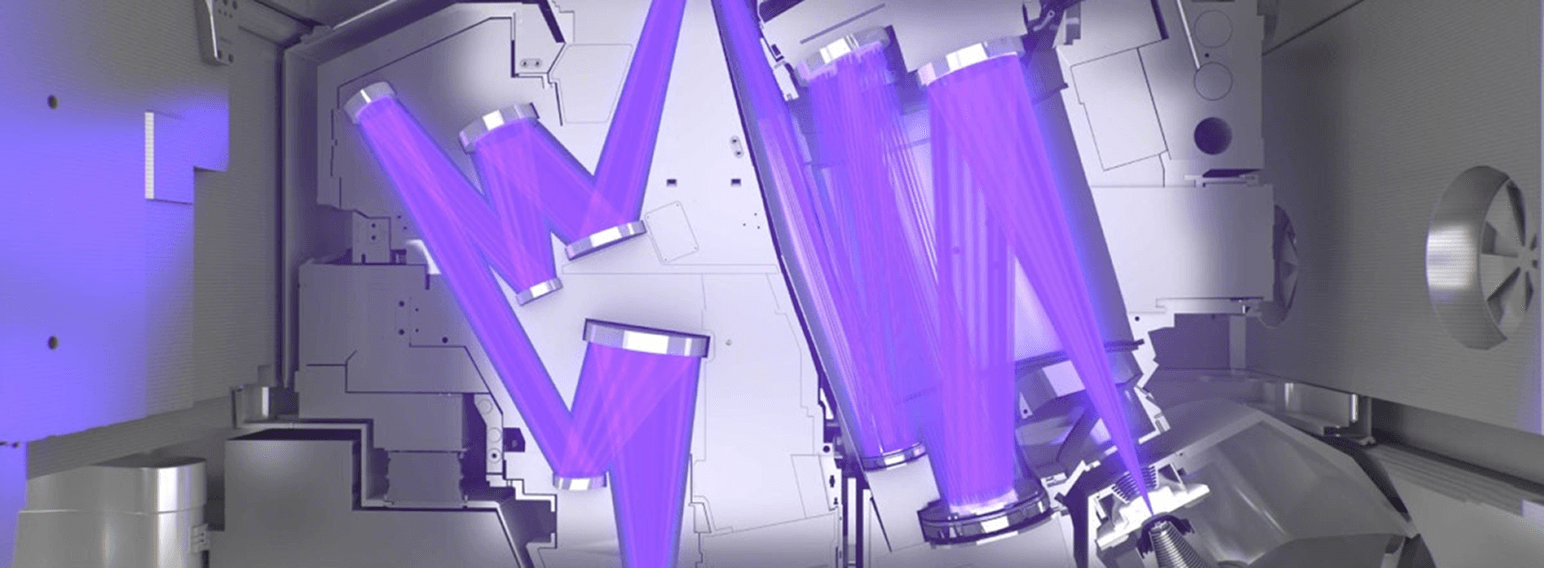

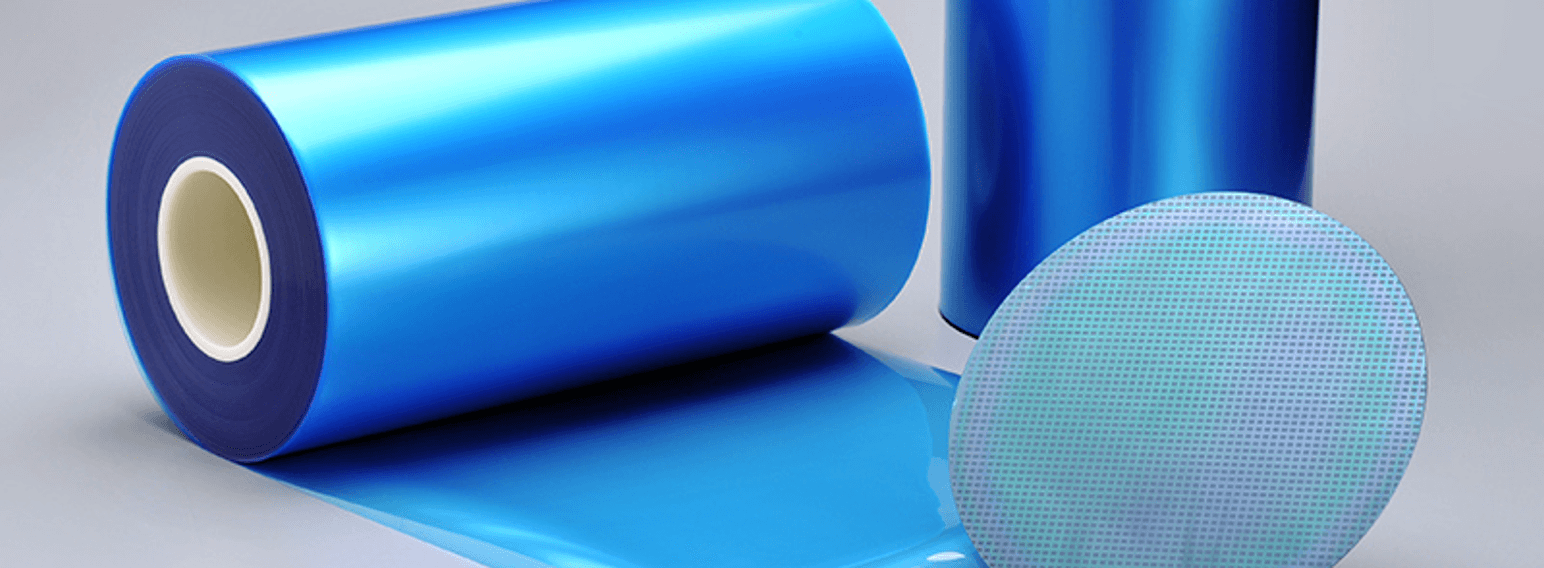

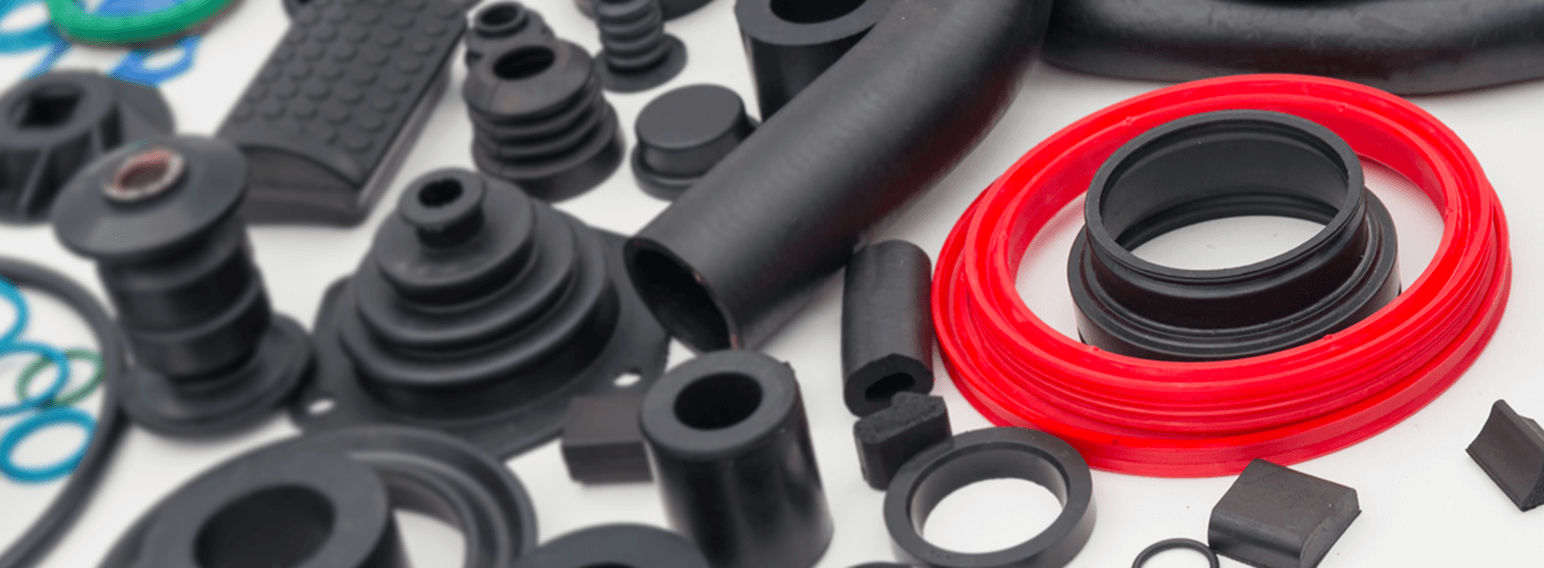

Graphene nanotubes provide durable ESD protection, clean performance, and improved wear resistance for wafer carriers, spacers, and vacuum-process components. When integrated into plastic parts, nanotubes enable FOUP and CASE solutions with significantly extended service life. Nanotube-enhanced coatings ensure a contamination-free operating environment, making them especially suitable for EUV and DUV processing.