Bionic

prosthetic

Graphene nanotubes for

prosthetics: affordable

touch-screen capability

TUBALL™ graphene nanotubes incorporated into the silicone fingertips of a bionic prosthetic arm enable the seamless integration of actuators, sensors, and electronic components that transmit electrical currents. This innovation provides bionic prostheses with touch-screen capability while preserving the softness and flexibility of the material without surface contamination.

Utilizing graphene nanotube-enhanced electrically conductive silicone, it becomes possible to add touch-screen functionality without requiring internal electronic circuits to generate and transmit electrical currents to the fingertips. This significantly reduces the cost of touch-screen-enabled prostheses, making them affordable. Thus, even a basic body-powered prosthesis can be touch-screen compatible.

Main properties

Electrical resistance

70–200 Ω

Softness

& flexibility

Touch-screen

compatible

No surface

contamination

Advanced bionic prosthetics

How do bionic prosthetics work?

Bionic prosthetics are advanced artificial limbs that replicate the natural movement and sensory feedback of real body parts. They achieve this by connecting directly to the user’s muscles and nerve endings, allowing seamless control and interaction.

Electrical conductivity is essential for bionic prosthetics because it enables the transmission of signals between the user’s nervous system and the prosthetic device, while also allowing the prosthetic device to interact with smart gadgets featuring touch-screen capability, making the prosthetic more intuitive and functional.

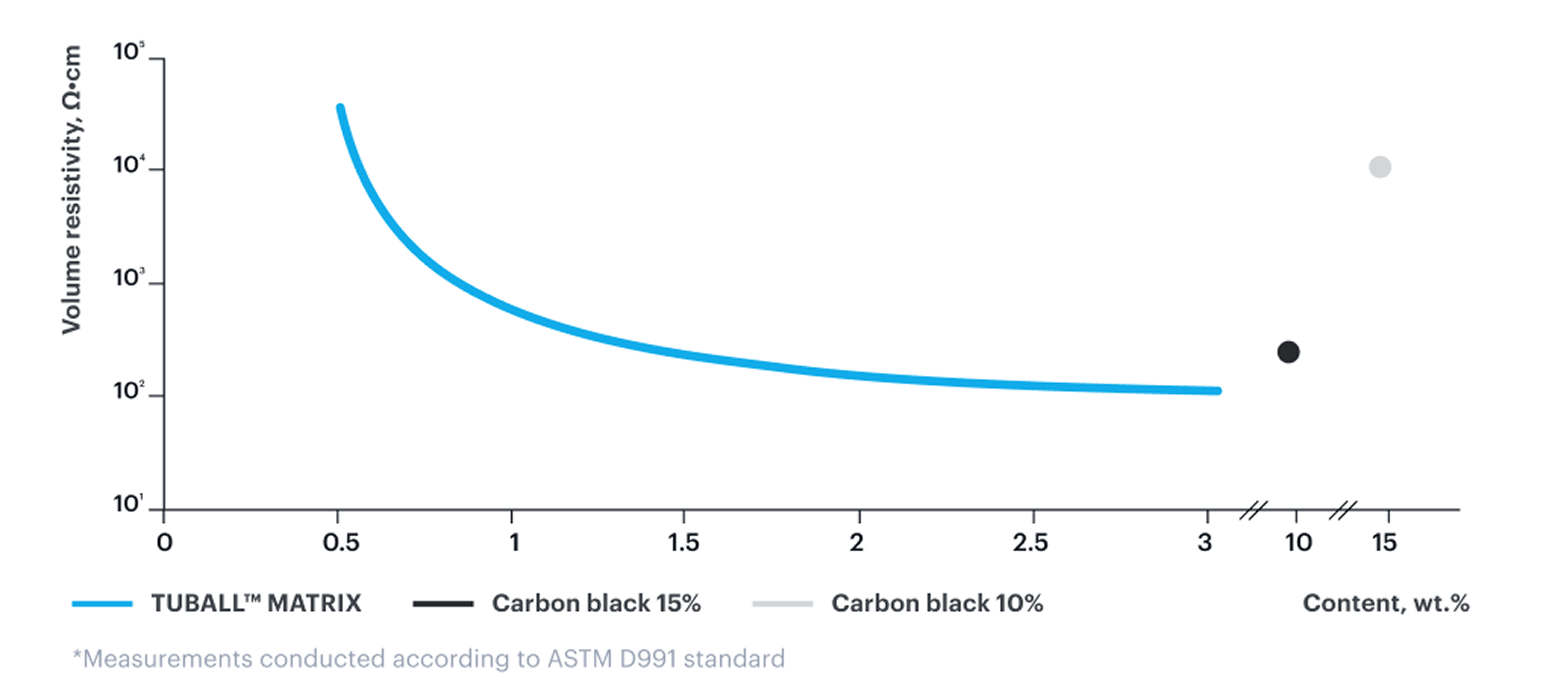

Stable electrical conductivity

TUBALL™ graphene nanotubes in room temperature vulcanized (RTV) silicone rubber form a conductive 3D network, ensuring stable, permanent electrical resistance of 70–200 Ω. This enables the silicone to transmit electrical impulses from the human body, making prosthetics touch-screen compatible.

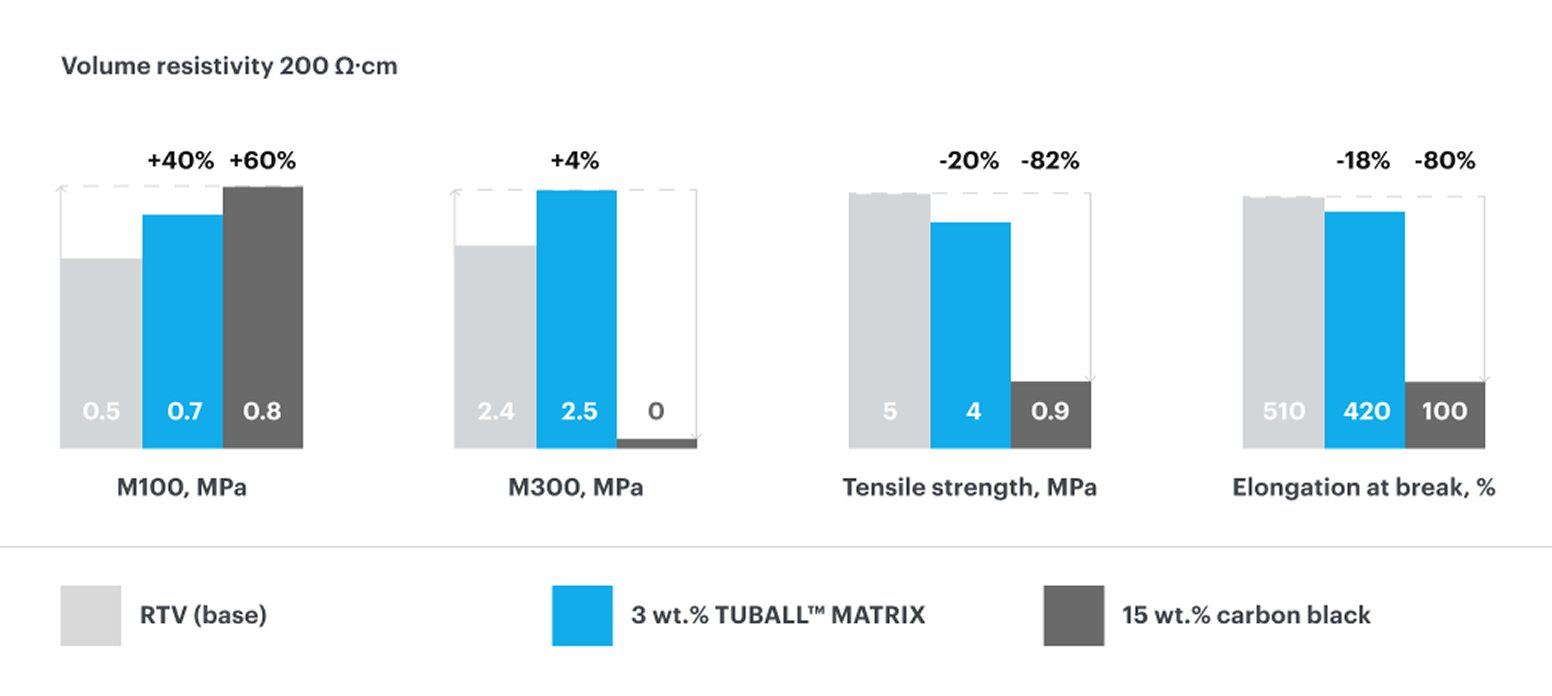

Preserved mechanical properties

In contrast to conventionally used carbon black, graphene nanotubes are effective at ultralow dosages. This enables significantly improved mechanical properties, such as a fourfold increase in tear strength for RTV silicone rubbers, while maintaining softness, elasticity, and strength compare to conventional fillers.

Retained color

TUBALL™ nanotubes enable the retention of various colors in the final product. This is possible thanks to the ultralow dosage of nanotubes, which cannot be achieved with standard conductive additives due to the high dosages required to get the necessary electrical conductivity.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

Additional benefits

Ultralow dosage

<1 wt.% TUBALL™

Dust-free production

Industry-friendly forms of nanotubes for standard processing

TUBALL™ MATRIX 601, 602, 613 are concentrates composed of a silicone-friendly carrier and pre-dispersed graphene nanotubes. It is specifically designed for liquid silicone rubbers (LSR) and room temperature vulcanised rubber (RTV), to enhance nanotube usability by ensuring an even dispersion of nanotubes in the host matrix while preserving low hardness. It minimizes the impact on compound elasticity, tensile properties, viscosity, and rheological characteristics, and ensures compatibility with standard mixing processes and equipment.

비가교결합형 전도성 첨가제 (액상 실리콘) : 색상이나, 점도(흐름성), 내구성에 미치는 영향이 적음

가교결합형 전도성 첨가제 (액상 실리콘) : 색상이나, 점도(흐름성), 내구성에 미치는 영향이 적음

Polydimethylsiloxane + zinc chloride (CAS-No. 7646-85-7) + zinc oxide (CAS-No. 1314-13-2)

Application cases

Related video

Graphene nanotubes for elastomers: consistent conductivity with high mechanical performance

Media on graphene nanotubes in medicine & healthcare

Graphene Nanotubes Could Reduce Costs of Prosthetics Interacting with Touch Screens

https://www.techtimes.com/articles/263418/20210727/graphene-nanotubes-reduce-costs-prosthetics-interacting-touch-screens.htmScientific validation

Electrostatic Dissipation in 3D-Printable Silicone

Low loadings (<1 wt %) of TUBALL™ can be sufficiently dispersed into silicone resins that can be 3D printed, and the resulting material shows a significant improvement in electrostatic dissipation through the reduction in electrical resistivity with minimal effect on its mechanical properties.