Graphene nanotubes for glass fiber filled PPS compounds with maintained mechanical properties and required processability

TUBALL™ 그래핀 나노튜브는 TUBALL™ MATRIX 821 베타 및 TUBALL™ MATRIX 808 형태의 다목적 전도성 첨가제로, 기계적 특성을 유지하면서도30–50 wt.% 유리 섬유 충전 PPS 화합물(glass fiber filled PPS compounds)에 허용 가능한 주입성을 제공하도록 특별히 설계되었습니다.

TUBALL™ 나노튜브를 GF-filled PPS 에 적용했을 때 나타나는 이점:

- Low dosage starting from 0.1 wt.% TUBALL™ graphene nanotubes to obtain conductive performance

- Enables a new combination of GF-filled PPS properties in comparison to standard conductive agents

- Maintains a good balance of mechanical properties

- Keeps the MFI level within an acceptable range for 30–50 wt.% glass fiber filled compounds

- Permanent, stable, and uniform electrical resistivity without “hot spots”

- Stable performance reducing the number of out-of-spec parts

- Good processability and easy handling

*Dosages may vary depending on the formulation, processing, and products.

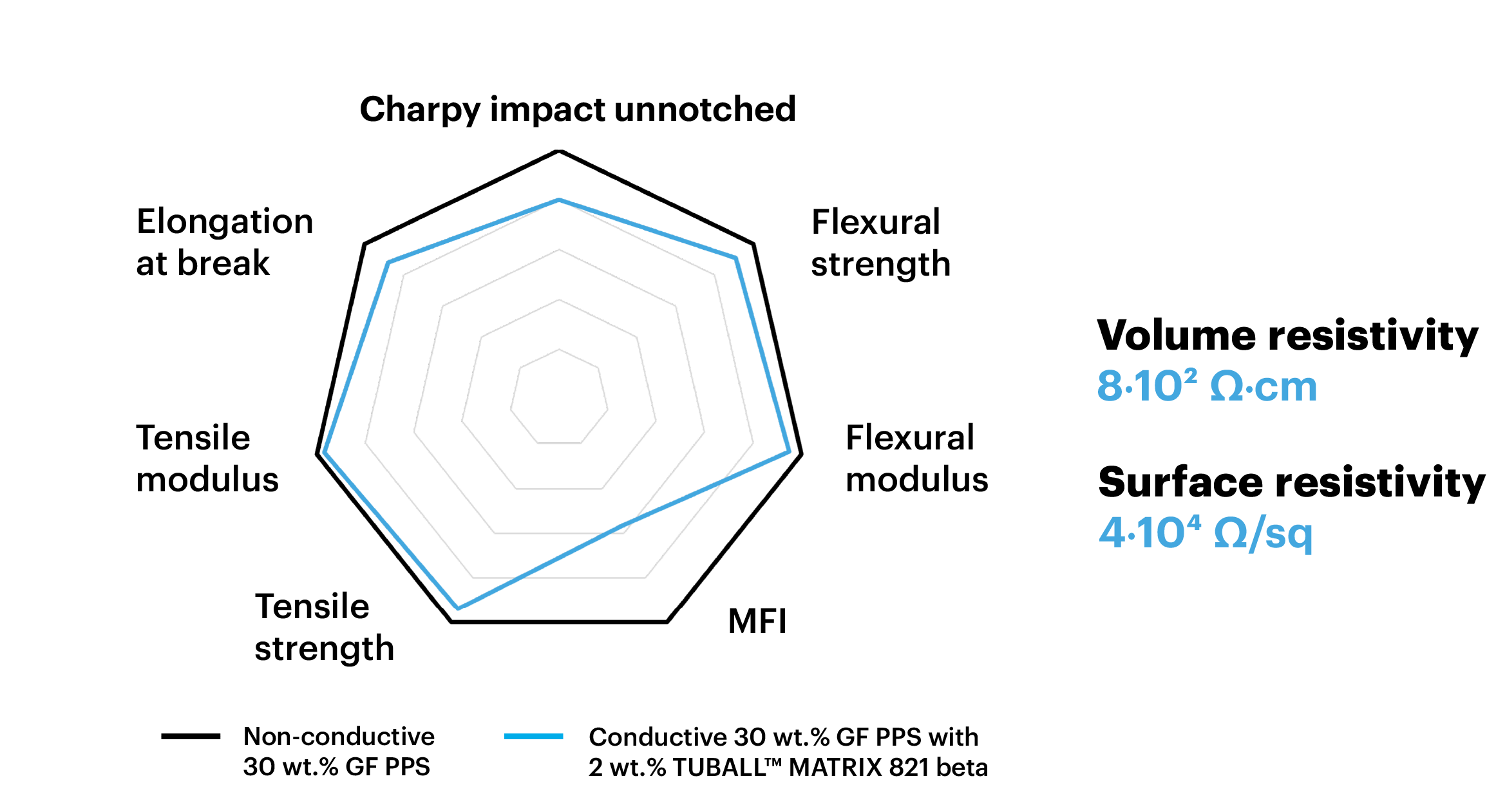

CONDUCTIVITY, PROCESSABILITY, MECHANICAL PERFORMANCE

Graphene nanotubes’ unique morphology allows them to create a dense conductive network inside thermoplastic compounds at low loading rates—starting from 0.1 wt.% in the total compound.

The use of TUBALL™ MATRIX preserves key mechanical properties and provides acceptable injectability.

Case: 2 wt.% TUBALL™ MATRIX 821 beta (0.2 wt.% TUBALL™ nanotubes) in 30 wt.% glass fiber filled PPS.

*OCSiAl internal study. Results may vary depending on the formulation, processing, and products.

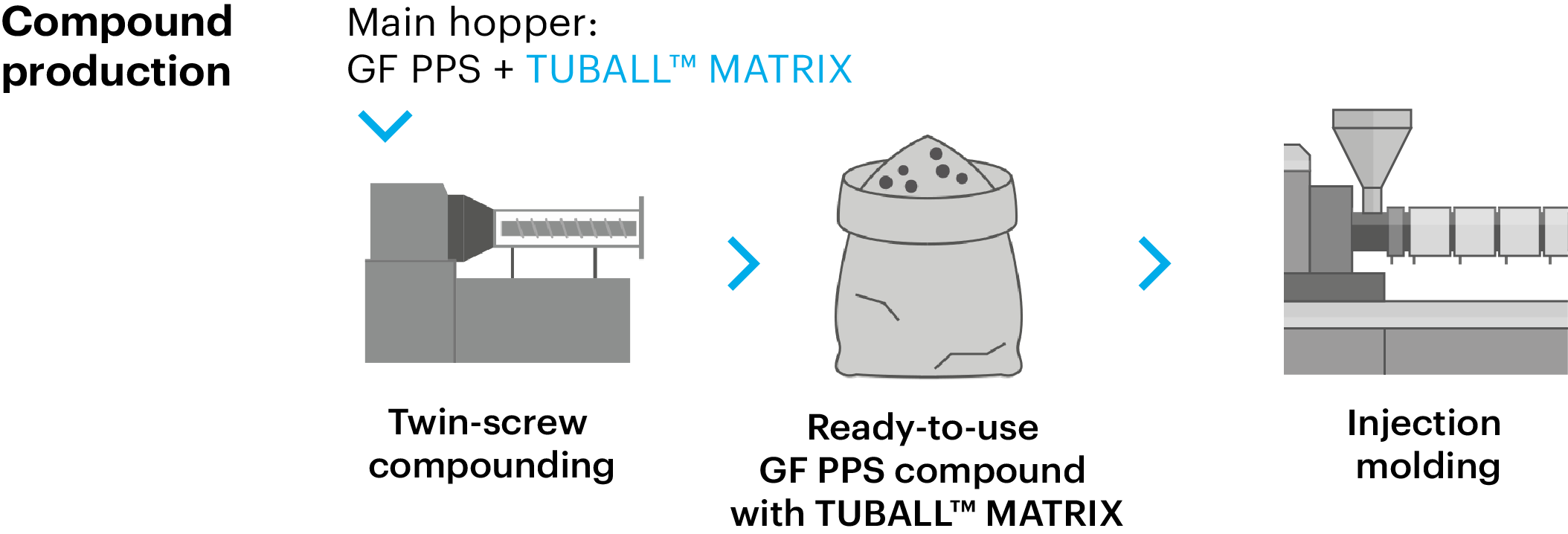

EASY-TO-APPLY WITH STANDARD EQUIPMENT

TUBALL™ MATRIX can be processed with standard equipment widely used in the thermoplastics industry.

Pay close attention to the processing guidelines for TUBALL™ MATRIX

Download PDF version:

전기차 팩 부품

TUBALL™ MATRIX for glass fiber filled PPS compounds

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample