Graphene nanotubes for medium voltage cable accessories: stable electrical conductivity and extended service life

Cable connectors, cable sleeves, and cable trays are widely used in electronic communications, energy, and electrical power systems. Parts of these engineering systems must be electrically conductive and fully screened and touchable to provide complete safety for personnel. Graphene nanotubes outperform conventional conductive additives, providing inner and outer semi-conductive layers of cable accessories with stable and consistent resistivity, longer service life due to enhanced strength, and easy processing thanks to the very low dosage required. This unique combination of properties not only ensures reliable cable protection even after aging but also delivers excellent surface quality and extended durability.

Main properties

Permanent volume resistivity

1.0 × 10⁸ Ω·cm

Improved mechanical

properties

Easy

processing

Anti-static cable accessories

What are cable accessories?

Medium voltage cable accessories are essential in power distribution, industrial installations, renewable energy, transportation, and construction—anywhere cables are terminated, joined, or connected, especially in high-voltage and sensitive environments. Semi-conducting layers in cables make the electric field manageable and uniform, eliminate high-voltage danger zones, and thereby significantly increase the reliability and service life of cable insulation.

To provide effective semi-conductive properties, they must meet strict volume resistivity requirements of <50 Ω∙cm.

Graphene nanotubes outperform traditional additives

Ultra-long, flexible, and conductive, graphene nanotubes form a robust 3D network in materials at ultralow concentrations of 0.15–0.3 wt.%. Unlike carbon black, multi-wall carbon nanotubes, and polymer-based anti-static agents—which require high dosages, lose conductivity over time, weaken mechanical properties, and complicate processing—graphene nanotubes enhance durability and ESD protection while preserving elasticity and hardness, outperforming conventional conductive additives across all key parameters.

- DIAGRAM

- TABLE

- TUBALL™

- MWCNT 1

- MWCNT 2

- Reference

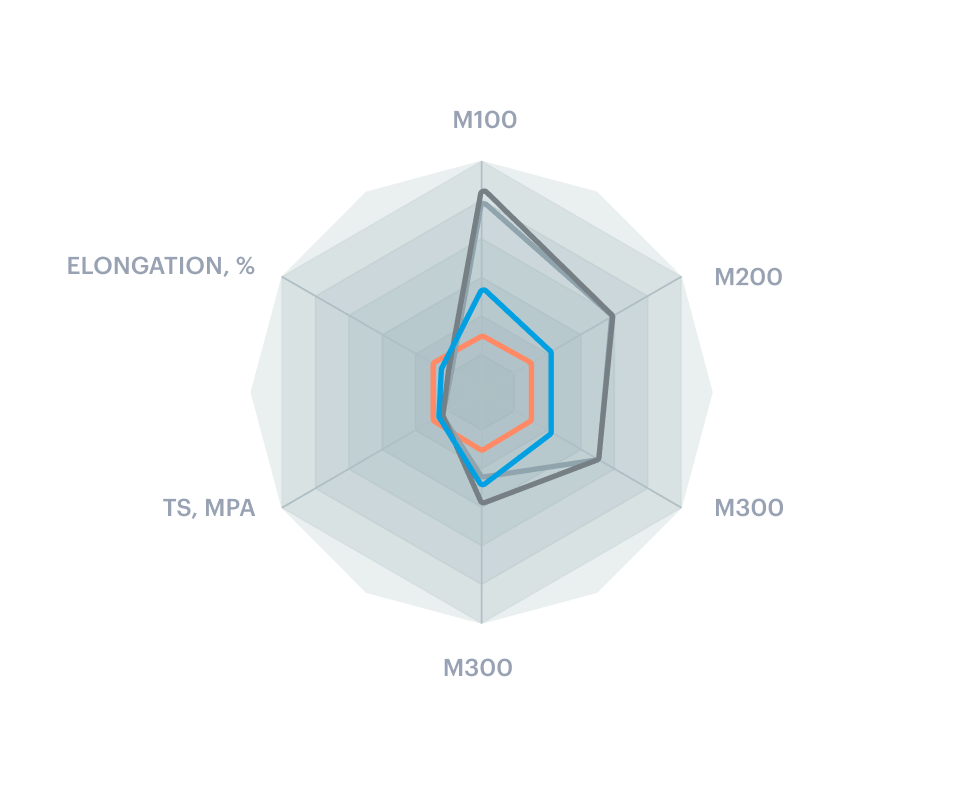

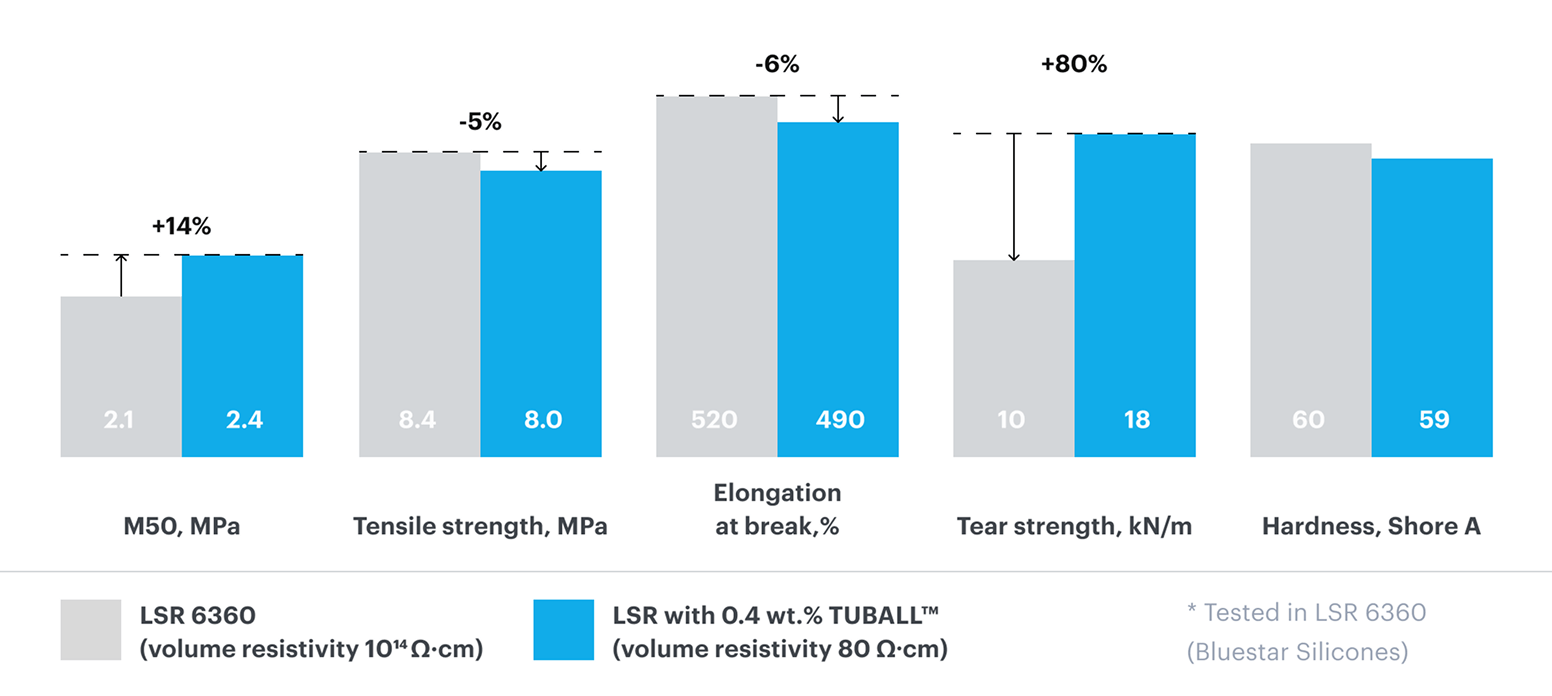

TUBALL™ allows to better maintain the balance of properties of the LSR

Permanent electrical conductivity

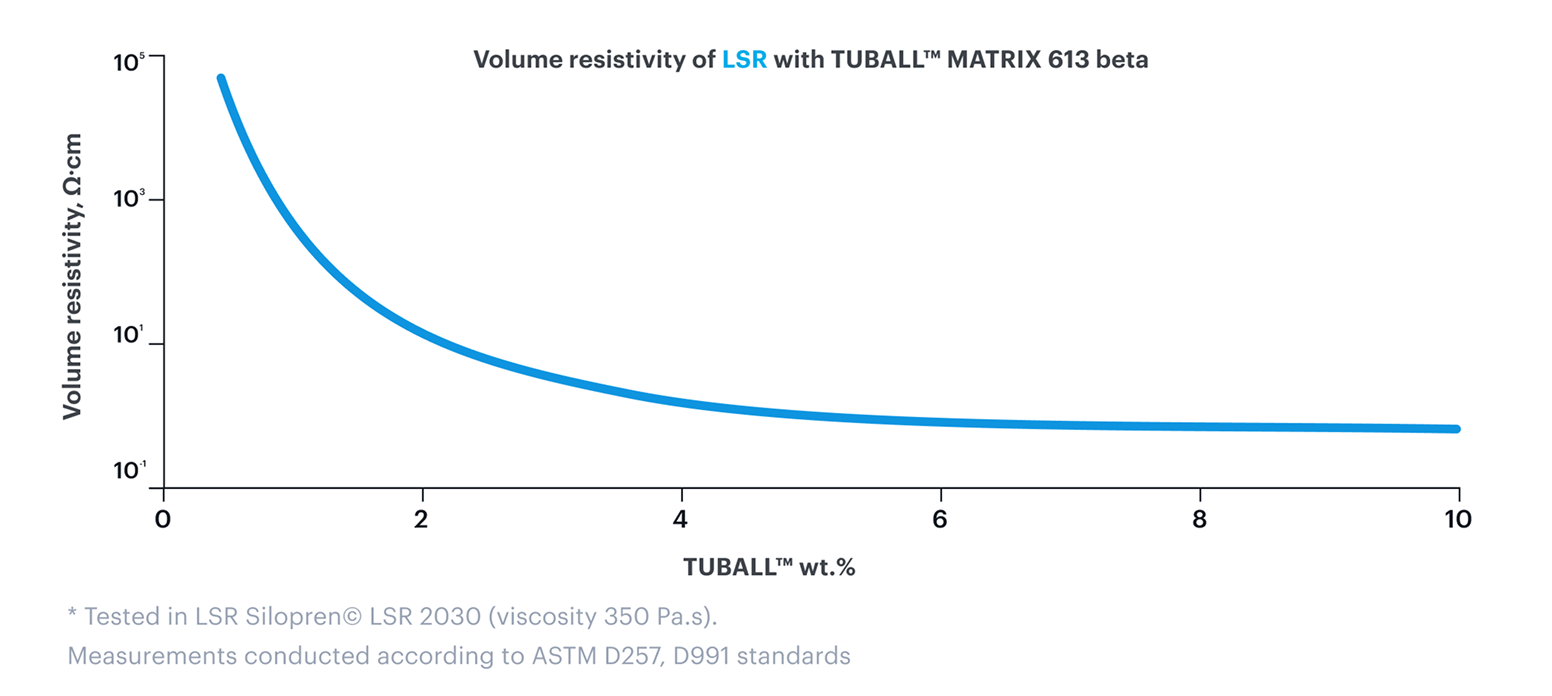

From 0.1 wt.%, TUBALL™ MATRIX in rubber forms a conductive 3D network, enabling a full range of electrical resistivity of 10–10⁸ Ω, not dependent on humidity and stable over a long service life, safeguarding people and sensitive devices from electrostatic charge and damage.

Improved mechanical performance

The distributed, uniform network created by TUBALL™ nanotubes within rubber significantly enhances mechanical properties such as tensile strength, elongation, and tear resistance, providing the end product with a longer service life.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

Additional benefits

Low hardness and

viscosity

No carbon release

to surface

Easy, clean

processing

Ready-to-use forms of nanotubes

TUBALL™ MATRIX 600 series is a line of concentrates with high-quality dispersed TUBALL™ graphene nanotubes designed for elastomers. They provide compatibility with standard processes and equipment. The concentrates can be added during the mixing or compounding stage and don’t affect the manufacturing process.

TUBALL™ MATRIX 601 je koncentrat grafenskih nanocevi koji je specifično dizajniran da obezbedi superiornu provodljivost u silikonskim smesama (LSR – tečna silikonska guma, RTV – guma vulkanizirana na sobnoj temperaturi) zadržavajući mehaničke osobine i uz minimalni uticaj na matricu domaćina. TUBALL™ MATRIX omogućava ultra niske doze provodnih filera za anti-statičke, statičke raspršene i provodne aplikacije. Proizvodnja provodnih smesa bez gubitka fleksibilnosti ili kompromitovanja mehaničkih osobina.

Kontaktirajte nas za kupovinu proizvoda od nanocevi. Cena zavisi od količine.

TUBALL™ MATRIX 602 je super koncentrat grafenskih nanocevi na bazi unakrsnog povezivanja nosača za tečne silikonske gume (LSR), gume vulkanizirane na sobnoj temperaturi (RTV) i gume visoke konzistentnosti (HCR) je specifično razvijen da unapredi upotrebljivost nanocevi obezbeđujući finu disperziju nanocevi u matrici domaćina održavajući mekoću.

Cena naših proizvoda od nanocevi sa jednim zidom zavisi od količine. Kontaktirajte nas za personalizovanu ponudu.

TUBALL™ MATRIX 605 je koncentrat grafenskih nanocevi koji je specifično dizajniran da obezbedi superiornu provodljivost u silikonskim smesama (HCR - gume visoke konzistentnosti) zadržavajući mehaničke osobine i uz minimalni uticaj na matricu domaćina. Provodni aditiv omogućava ultra niske doze koje počinju od 0,5 wt.% za anti-statičke, statičke raspršene i provodne aplikacije.

Kontaktirajte nas za kupovinu proizvoda od nanocevi. Cena zavisi od količine.

TUBALL™ MATRIX 610 je svestrana pigmentna disperzija koja je specifično dizajnirana za smese EPDM gume.

TUBALL™ nanocevi obezbeđuju trajni, stabilan nivo električne provodljivosti i unapređuju mehaničke osobine različitih tipova EPDM.

Cena naših proizvoda od nanocevi sa jednim zidom zavisi od količine. Kontaktirajte nas za personalizovanu ponudu.

Polydimethylsiloxane + zinc chloride (CAS-No. 7646-85-7) + zinc oxide (CAS-No. 1314-13-2)

Media

Anti-static and conductive hand layup composites: How to produce using graphene nanotubes