Clean-room

ESD gloves

Graphene nanotubes for

clean-room ESD gloves:

industry standard compliance

and color variety

Clean-room gloves classified as ISO Class 4–8 must be anti-static to prevent electrostatic discharge (ESD), which can damage sensitive electronics or disrupt production. Graphene nanotubes are the only material currently available on the market that provides a permanent, humidity-independent anti-static effect in nitrile gloves while requiring only minimal changes to the manufacturing process. The resulting electrical conductivity not only ensures reliable ESD protection in compliance with clean-room glove standards (IEC 61340-4-9 and ANSI STM11.11) but also enables seamless touch-screen use without removing the gloves and wide color variety.

Main properties

Electrical resistivity of

< 1.0 × 10⁸ Ω

Compliance with

international

standards

Touch-screen

compatibility

Color

flexibility

Anti-static clean-room gloves

What are clean-room gloves?

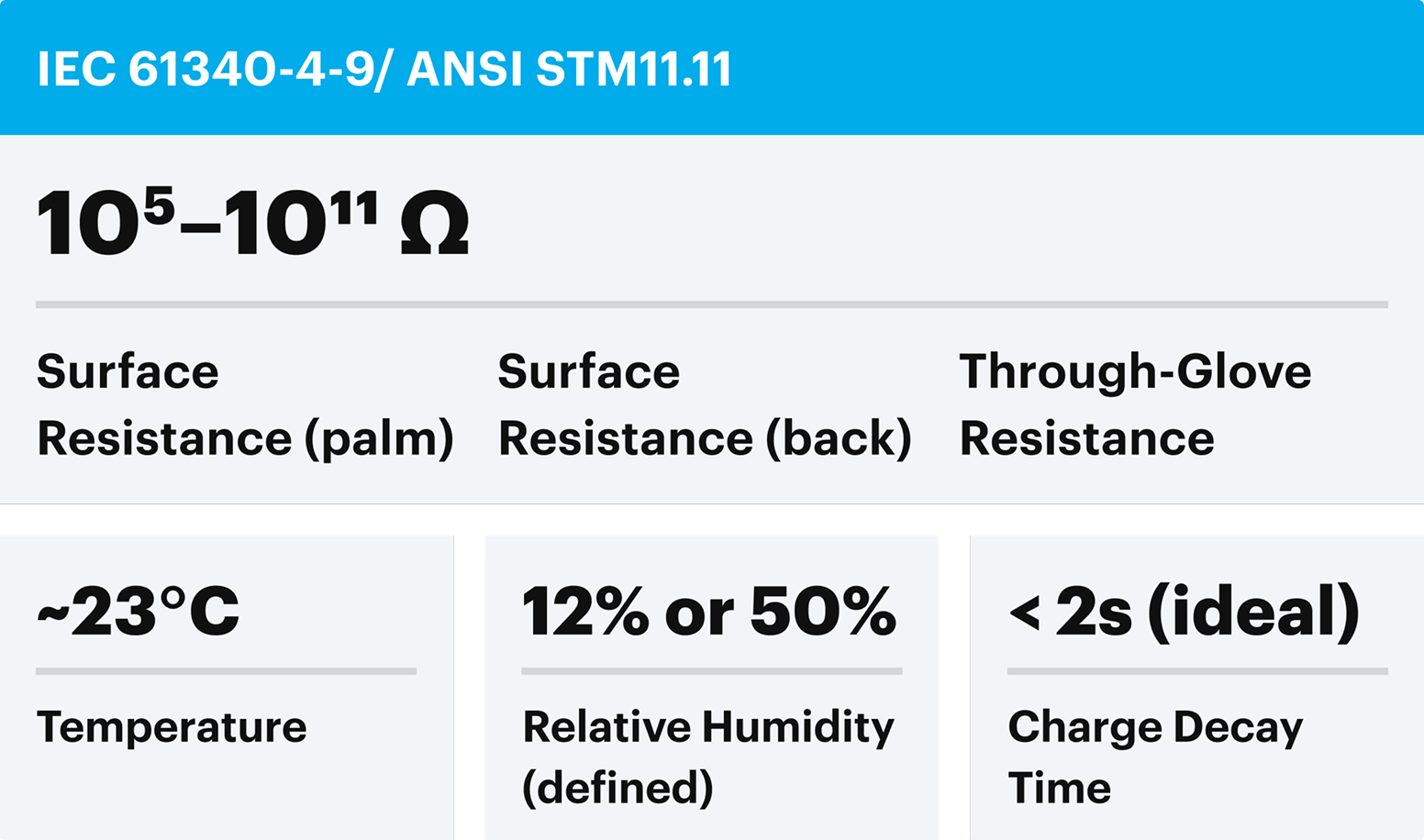

Clean-room gloves are essential for contamination control and ESD protection, primarily in electronics, semiconductors, aerospace, and pharma. They protect both workers and sensitive products. Anti-static gloves are engineered to safely dissipate static electricity from workers’ hands, protecting sensitive equipment and processes in such environments as electronics manufacturing or pharmaceutical production sites. To ensure effective ESD protection, they must meet strict volume resistivity requirements—below 10⁵–10¹¹ Ω—in compliance with the IEC 61340-4-9 / ANSI STM11.11 standards as well as preserving other vital properties such as particle generation, low outgassing, clean-room classification, and chemical resistance.

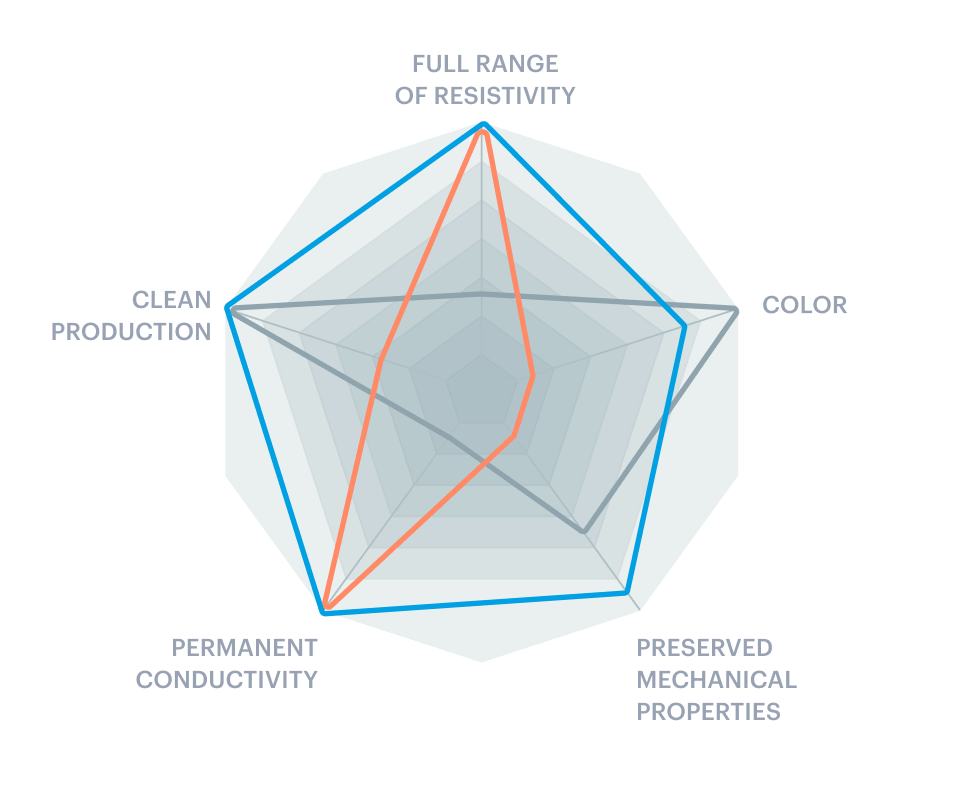

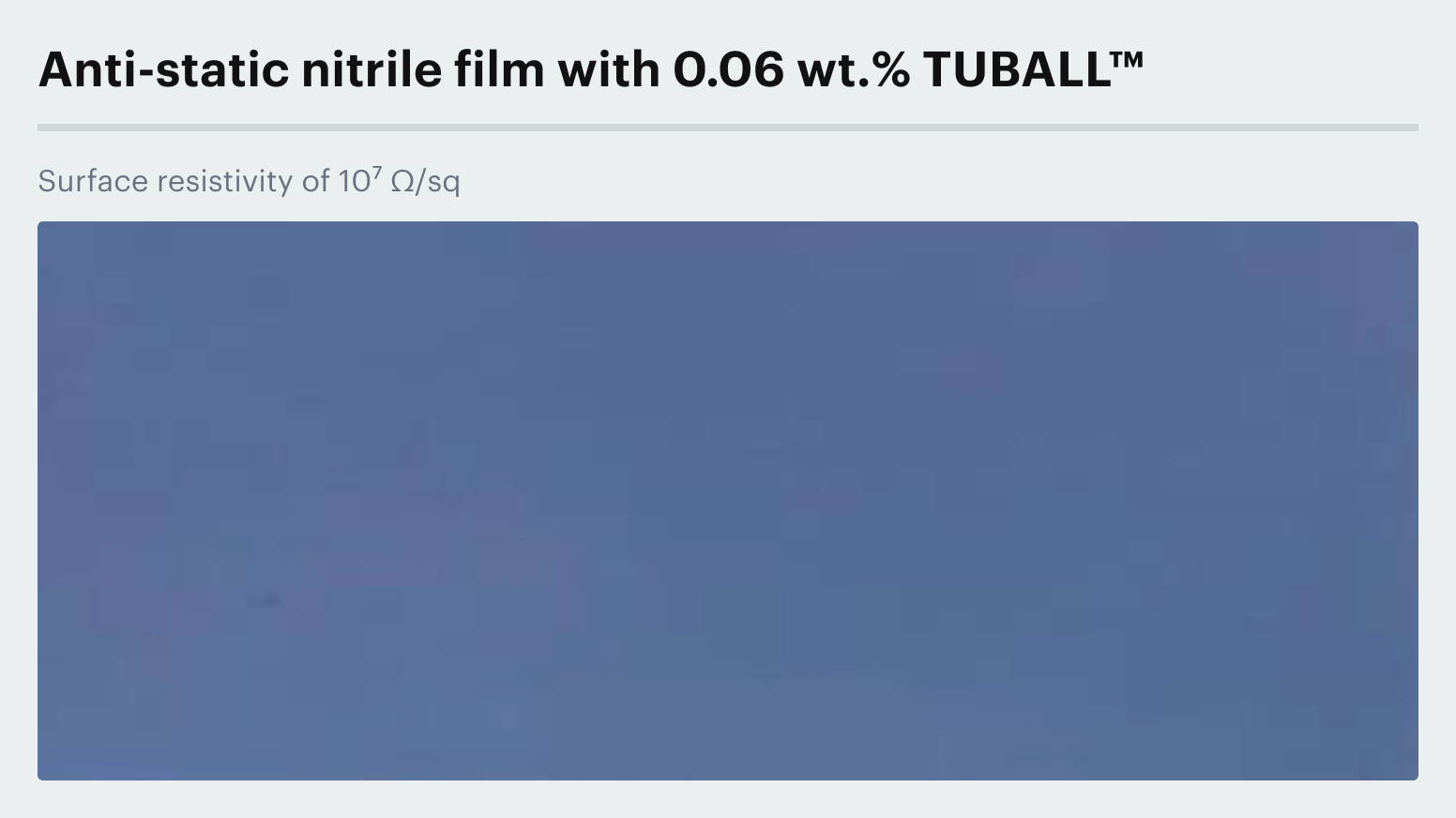

Graphene nanotubes surpass traditional additives

Ultra-long, flexible, and electrically conductive, graphene nanotubes create a robust 3D network within materials at ultralow concentrations of just 0.05–0.1 wt.%. They offer a stable alternative to traditional polymer or salt-based coatings, which can be prone to degradation. Thanks to their unique properties, graphene nanotubes enhance durability and ESD protection while preserving the material’s original color and softness. As a result, they outperform conventional conductive additives across all key performance parameters.

- DIAGRAM

- TABLE

- TUBALL™ nanotubes

- Carbon black-based dispersion

- Ammonium salts

* This diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

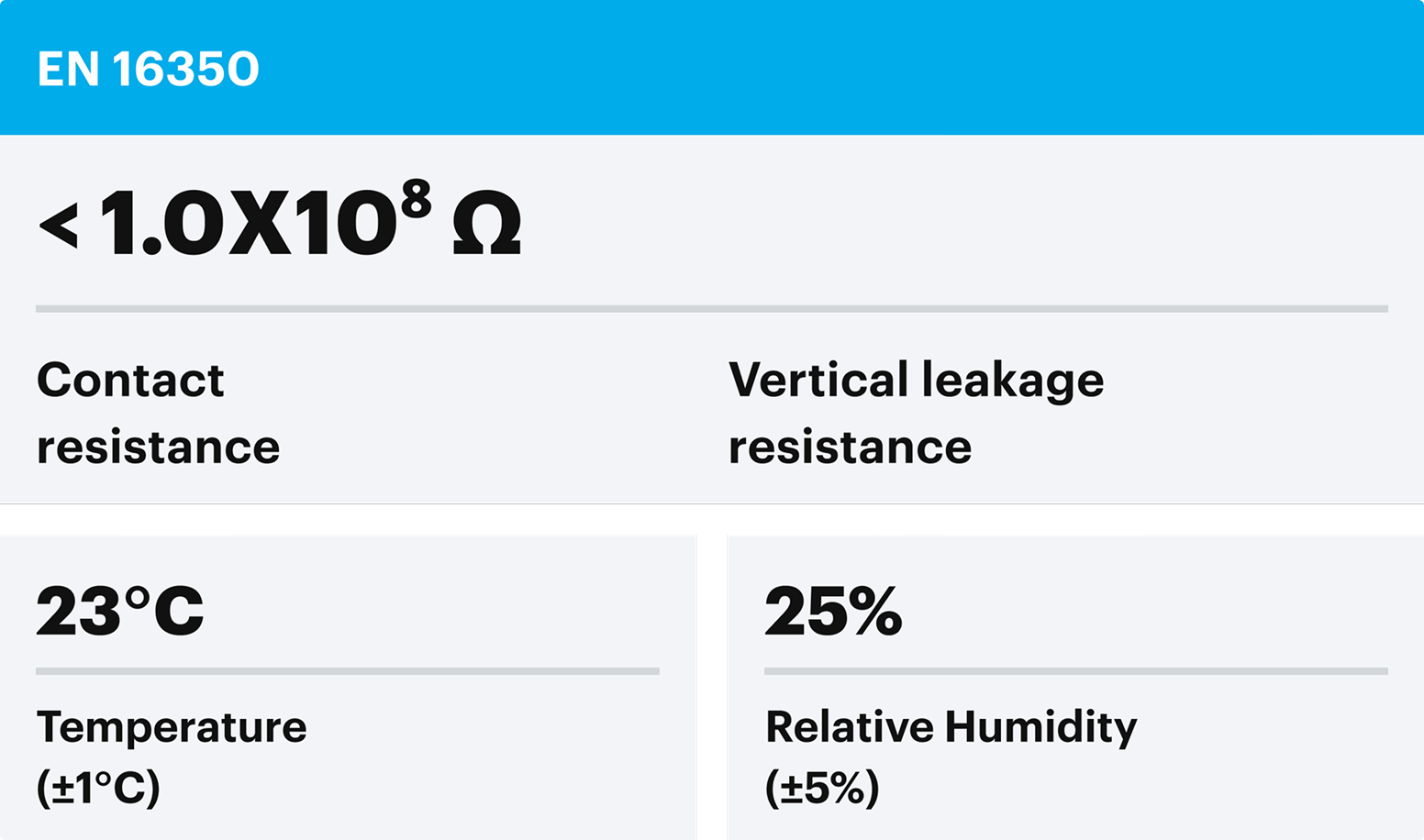

Gloves’ compliance with ESD glove standards

As industrial automation advances, ESD safety standards are becoming stricter. The IEC 61340-4-9 / ANSI STM11.11 and EN 16350 standards for gloves raised the bar, limiting the use of many traditional anti-static additives. Graphene nanotubes rise to the challenge, delivering permanent, humidity-independent conductivity that fully complies with the latest standards in ESD protection as well as providing required performance to clean-room gloves suitable for electronics, semiconductors, EV batteries, and many more applications classified as ISO Class 4–8.

Wide variety of colors

Thanks to an ultralow working dosage, graphene nanotubes make it possible to achieve required anti-static performance in all water-based latex systems while preserving color variety.

Compatibility with touch screens

TUBALL™ graphene nanotubes deliver reliable anti-static protection while enabling seamless touch-screen use—no need to remove your gloves. They protect both workers and sensitive products, combining safety with convenience.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

Additional benefits

Robust

conductive coating

Standard

dipping process

Maintained mechanical

properties

Dust-repellent

performance

Ready-to-use forms of nanotubes

TUBALL™ LATEX is a water-based suspension with high-quality dispersed TUBALL™ graphene nanotubes and is compatible with all latex types. It is designed to integrate seamlessly with standard processes and equipment. The dispersion can be added during the latex compounding stage and doesn’t affect the manufacturing process.

Application cases

Related video

ESD Colored Latex Gloves: New Standard

Media on graphene nanotubes in gloves

OCSiAl licences nanotube technology to latex gloves maker

https://www.european-rubber-journal.com/article/2093708/ocsial-licences-graphene-nanotube-tech-to-sri-lanka-latex-maker

Graphene nanotubes outperform PPE alternatives

https://www.innovationintextiles.com/graphene-nanotubes-outperform-ppe-alternatives/

Protective Equipment with Graphene Nanotubes Meets the Strictest ESD Safety Standards

https://www.pcimag.com/articles/110179-protective-equipment-with-graphene-nanotubes-meets-the-strictest-esd-safety-standards

New standard for anti-static and ESD gloves – New Solution

https://www.european-rubber-journal.com/article/2064014/new-standard-for-anti-static-and-esd-gloves-new-solutionScientific validation

Single-Wall Carbon Nanotube Latexes

Natural Rubber-Carbon Nanotube Composites through Latex Compounding