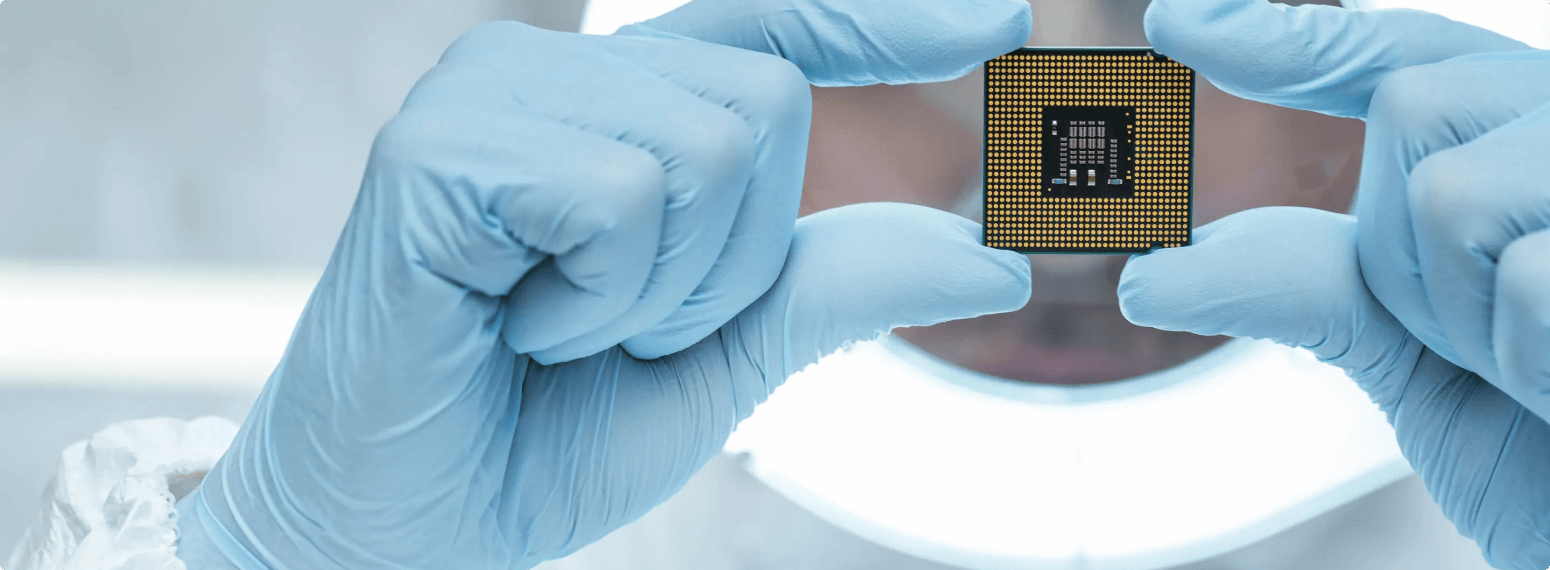

Industrial gloves

Graphene nanotubes offer stable, permanent ESD protection and an anti-static effect, allowing seamless touch-screen operation without removing work gloves. This ensures both worker and product safety and compliance with the EN 16350 standard.

Read more