Industrial gloves

Graphene nanotubes for

ESD-protective gloves: safety &

ease of touch-screen operations

Work gloves used in ATEX areas should be anti-static to dissipate static electricity effectively. ESD protection is obligatory in electronics manufacturing, the petrochemical industry, and for handling flammable gases or liquids. Graphene nanotubes are a unique anti-static agent, delivering a permanent, humidity-independent anti-static effect to nitrile, latex, and polyurethane coated gloves. The provided electrical conductivity grants an anti-static effect that allows for seamless touch-screen use without the need to remove gloves. This ensures the highest levels of safety for both workers and products in compliance with safety glove standards and PPE requirements.

Main properties

Electrical

resistivity of

<1.0x10⁸Ω

Touch-screen

compatibility

Standard

processing

Color

flexibility

Anti-static industrial gloves with touch-screen capability

What are anti-static gloves?

Anti-static gloves are specialized gloves designed to prevent the buildup and discharge of static electricity from the workers’ hands. These ESD-protective gloves must meet volume resistivity requirements of less than 1.0 × 10⁸ Ω, complying with the EN 16350 standard.

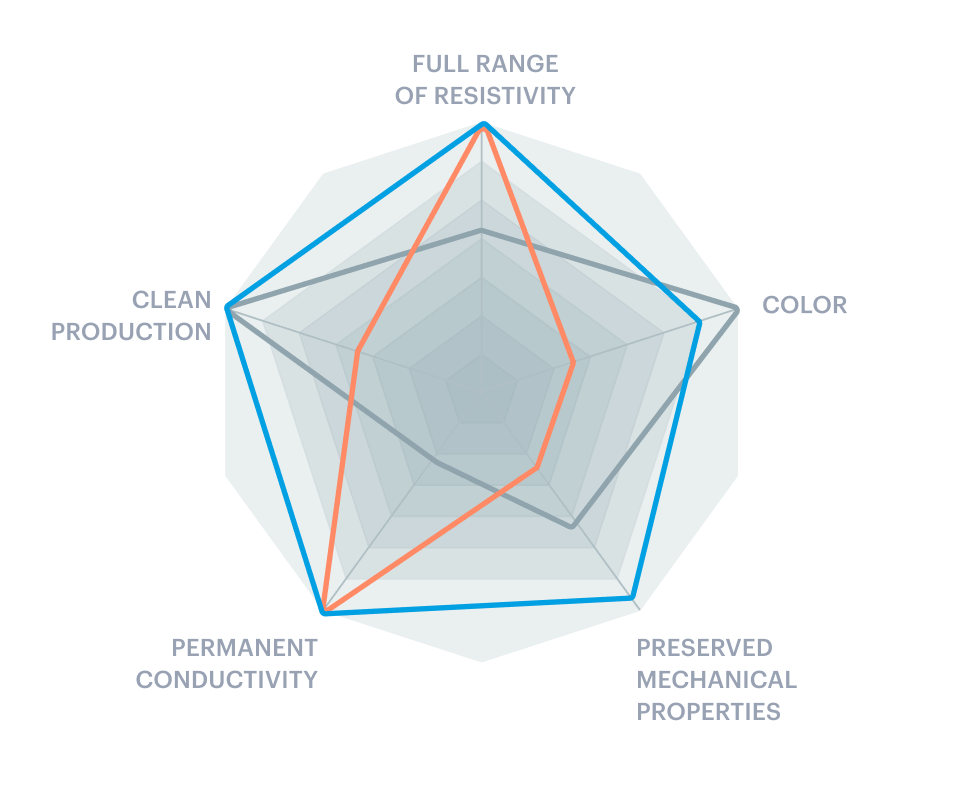

Graphene nanotubes outperform standard additives for ESD-protective gloves

Ultra-long, electrically conductive, and flexible, graphene nanotubes form a 3D conductive and reinforcing network inside materials at extremely low dosages of 0.06–0.1 wt.%. The unique properties of nanotubes make it possible to maintain resistance to microbial attack, abrasion, alkali, and hydrolysis, while enhancing durability, ESD reliability, and a special soft-feel effect. This allows them to show better results compared to conventional conductive agents in all parameters of the modified material.

- DIAGRAM

- TABLE

- TUBALL™

- Carbon black

- Ammonium salts

Gloves’ compliance with EN 16350 standard

ESD safety standards are evolving alongside industrial automation. The EN 16350 standard for the electrostatic properties of protective gloves has significantly restricted the use of conventional antistatic additives that cannot meet its stricter requirements. Alternatives such as carbon or metallic yarns require complex knitting processes and limit the choice of top coatings. As a result, manufacturers have sought solutions that comply with the standard while maintaining touchscreen compatibility and avoiding major production investments. Graphene nanotubes address these needs by providing permanent, humidity-independent conductivity that meets the updated European requirements for a wide range of antistatic glove applications—without changes to existing manufacturing technology.

23°C

Temperature (±1°C)

25%

Humidity (±5%)

< 1.0x10⁸ Ω

Contact resistanceVertical leakage resistance

Compatibility with touchscreens

TUBALL™ graphene nanotubes provide an anti-static effect that allows smooth operation of touch screens without the gloves having to be removed and that ensures worker and product protection.

Combining color and anti-static properties is possible

Graphene nanotubes make it possible to achieve required anti-static performance in all water-based latex and polyurethane systems. The dosage required varies depending on the formulation, coating thickness, and glove design. The extremely low dosage of graphene nanotubes required opens the door to produce colorful solutions where desired.

Colored anti-static nitrile film with 0.06 wt.% of TUBALL™

Surface resistivity of 10⁷ Ω

Additional benefits

Maintained compounding and dipping process

Preserved or improved mechanical properties

Can be used with standard liners without conductive yarns

Industry friendly forms of nanotubes compatible with standard processing

TUBALL™ LATEX is a water-based suspension with high-quality dispersed TUBALL™ graphene nanotubes and stabilized with latex-friendly chemicals. It is designed to provide compatibility with standard processes and equipment. The dispersion can be added during the latex or polyurethane compounding stage and doesn’t affect the manufacturing process.

TUBALL™ LATEX

Contact us to discuss your project specifications or to request a TUBALL™ LATEX sample

Agent antistatique pour composés de latex colorés : une solution simple d’utilisation, entièrement conforme aux réglementations de protection contre l’accumulation de la charge statique

Application cases

Related video

ESD Colored Latex Gloves: New Standard

Media on graphene nanotubes in industrial ESD gloves

Graphene nanotube dispersion for latex gloves meeting ESD standards to be produced in Sri Lanka

https://www.jeccomposites.com/news/spotted-by-jec/graphene-nanotube-dispersion-for-latex-gloves-meeting-esd-standards-to-be-produced-in-sri-lanka/

Graphene nanotubes outperform PPE alternatives

https://www.innovationintextiles.com/graphene-nanotubes-outperform-ppe-alternatives/

Novel Smart Textiles – Graphene Nanotubes Add Functionality To Yarns

https://www.textileworld.com/textile-world/nonwovens-technical-textiles/2022/07/novel-smart-textiles-graphene-nanotubes-add-functionality-to-yarns/