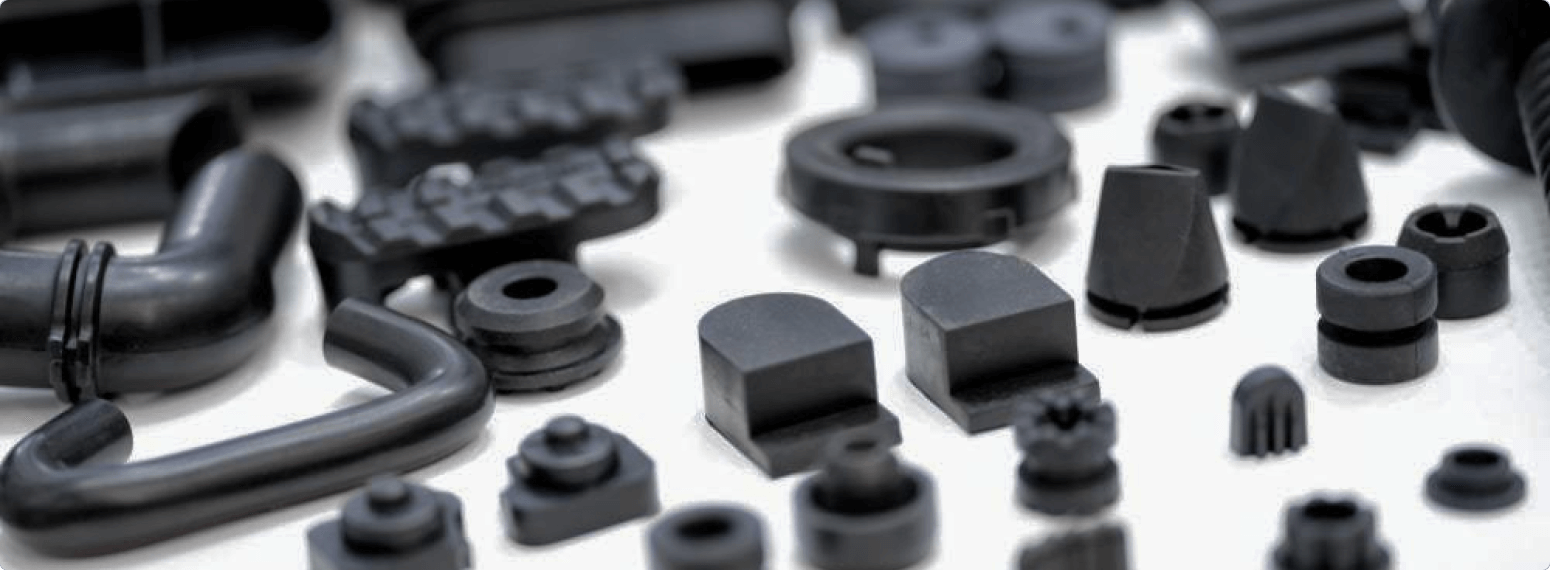

Auto tires

Graphene nanotubes allow for fine-tuning formulations to achieve the required electrical dissipation in tires without compromising wet grip, energy efficiency, handling, or vehicle safety. Taber abrasion tests find no free-standing nanotubes are released from tire tread wear.