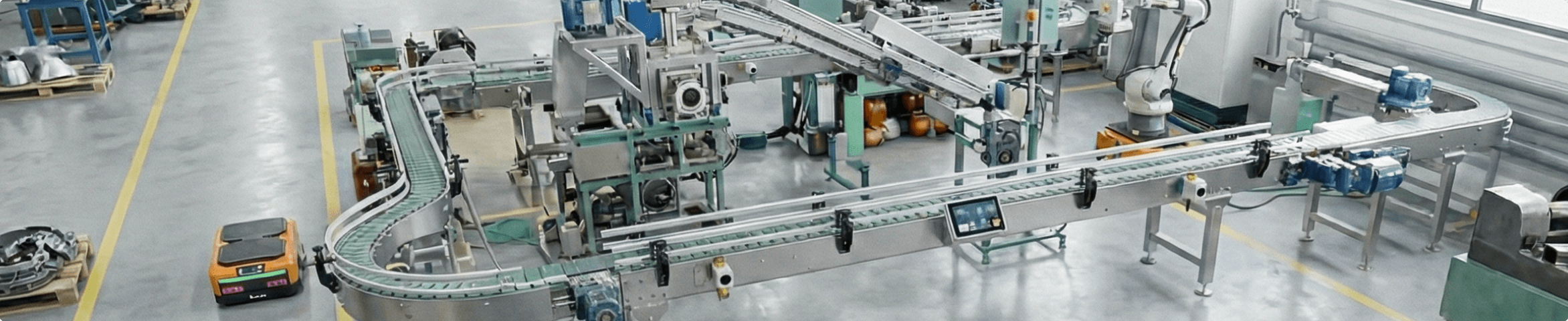

Conveyor equipment parts

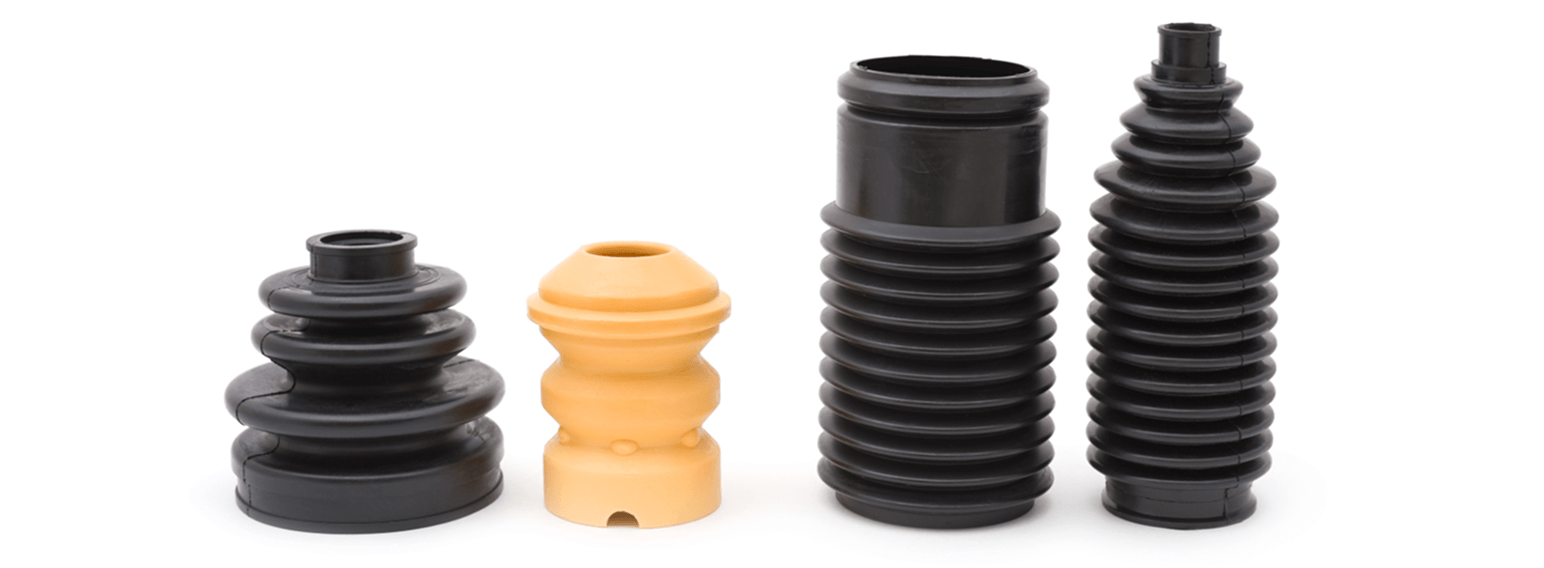

Graphene nanotube-enhanced rollers, sleeves, and dampers deliver stable ESD-safe performance, preventing static buildup that can damage products or endanger workers. They also offer superior tensile strength, adhesion, and wear resistance, with no carbon migration to the surface.