Massage

devices

Graphene nanotubes for massagers: enhanced functionality and skin comfort

TUBALL™ graphene nanotubes provide electrical impulse massagers with stable and uniform electrical conductivity while preserving the original softness of silicone. Foot, head, and neck massage devices enhanced with nanotubes ensure no skin contamination or irritation, offering superior comfort and safety.

The healthcare industry demands highly conductive materials for pulse massagers to deliver electrical impulses to the human body effectively. At the same time, these materials must be soft and flexible for skin-contact applications, making silicone an ideal choice. By integrating graphene nanotubes, silicone-based massage devices achieve improved functionality, preserve skin cleanliness, and offer superior comfort.

Main properties

Stable electrical

performance

(R<100Ω)

Softness

& flexibility

No skin

contamination

Massage devices for healthcare

What is an electronic pulse massager?

An electronic impulse massage device uses electrical signals to stimulate muscles, improve blood circulation, and relieve tension. These devices are commonly used in physical therapy, fitness recovery, and wellness routines to reduce pain, enhance muscle performance, and promote relaxation.

To perform effectively, these devices require stable electrical conductivity and skin-friendly properties. Originally insulative silicone, valued for its softness and flexibility, must be enhanced with a conductive additive to maintain these qualities while ensuring optimal performance.

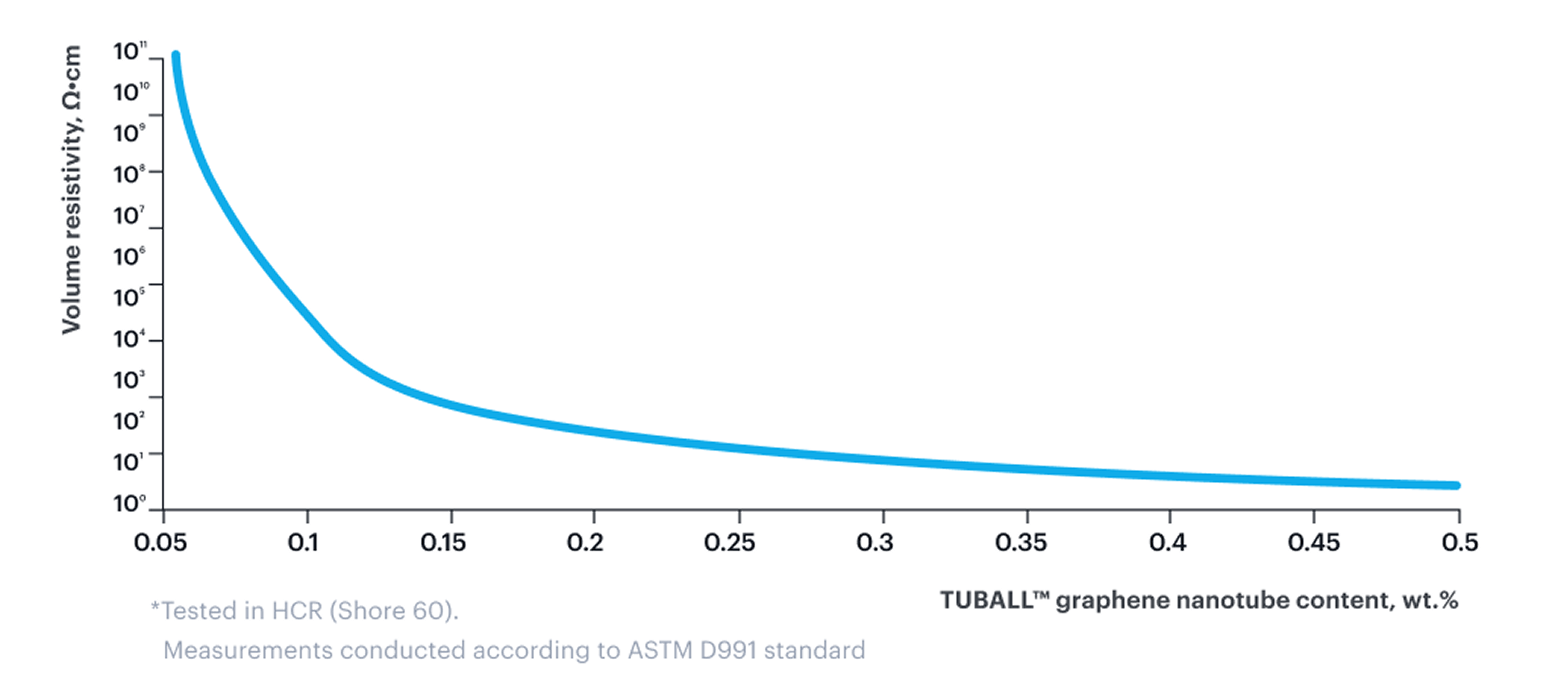

Electrical conductivity at ultralow dosage

With a dosage as low as 0.25 wt.%, graphene nanotubes replace up to 40 wt.% carbon black in a conductive high-consistency rubber (HCR) silicone compound, ensuring stable volume resistivity of <100 Ω•cm. This combination of functionality and comfort is crucial for materials used in healthcare devices.

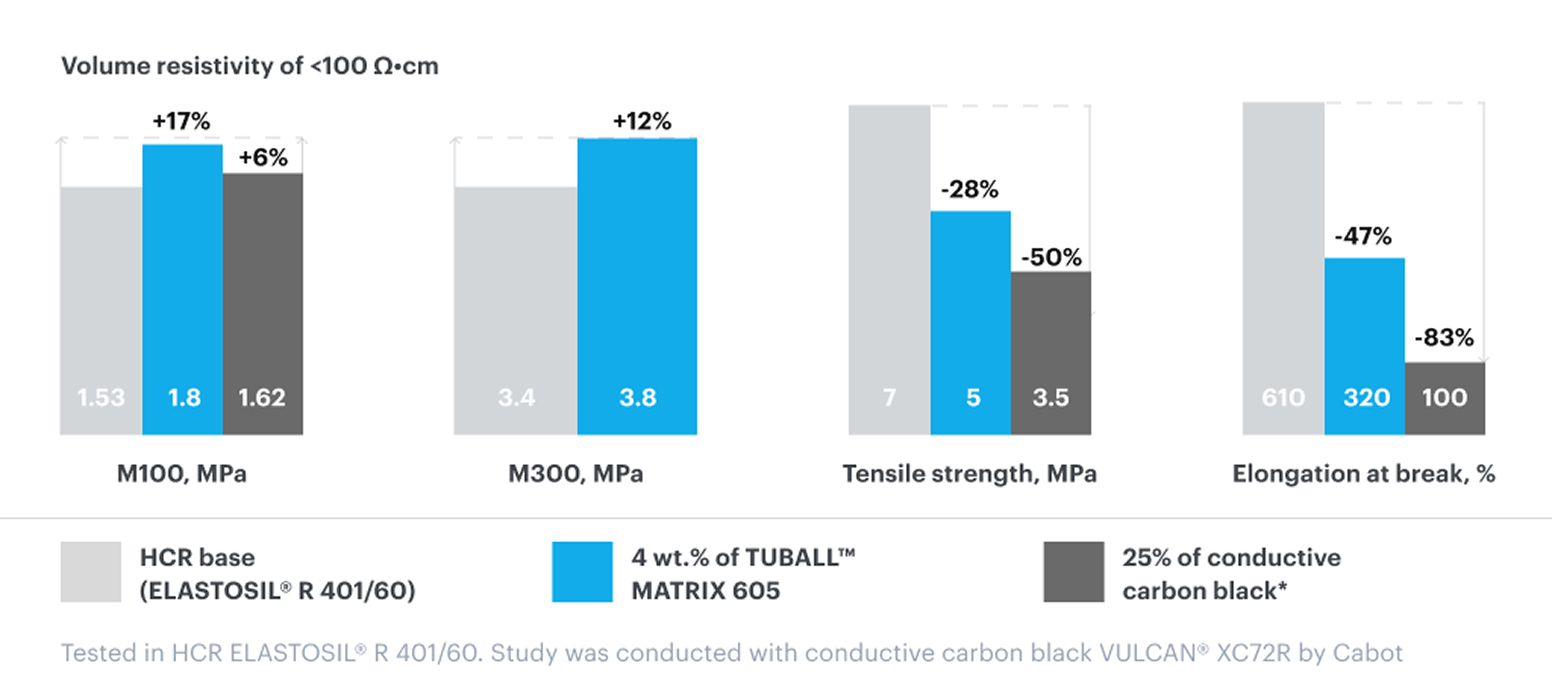

Preserved mechanical properties

In contrast to conventionally used carbon black, TUBALL™ graphene nanotubes work effectively at ultralow dosages. This allows silicone to maintain softness, elasticity, low hardness, tensile parameters, viscosity, and rheological properties.

Skin cleanliness

The nanotubes are fully incorporated into the material, eliminating carbon release to the material’s surface and skin contamination or irritation. TUBALL™ in powder form has successfully passed toxicology risk assessments related to skin safety.

- Skin corrosion test (OECD 431)

- Skin irritation test (OECD 439)

- Skin sensitization test (OECD 406)

- Acute dermal toxicity test (OECD 402)

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

Additional benefits

Non-dusty production

Easy processability

Industry-friendly forms of nanotubes for standard processing

TUBALL™ MATRIX 605 is a concentrate based on reactive polymer and pre-dispersed graphene nanotubes. It is specifically designed for high consistency rubber (HCR) silicone systems to provide compatibility with standard mixing processes and equipment. It can be added during the silicone compounding stage and doesn’t affect the manufacturing process.

TUBALL™ MATRIX 601 is a graphene nanotube-based concentrate specifically designed to provide superior electrical conductivity to silicone compounds (LSR – liquid silicone rubber, RTV – room temperature vulcanized rubber) while retaining mechanical properties and minimally impacting the host matrix. TUBALL™ MATRIX enables ultra-low dosage of conductive filler for anti-static, static dissipative and conductive applications. Produce conductive compounds without losing flexibility or compromising mechanical properties.

To buy nanotube products, please contact us. Price depends on the required volumes.

TUBALL™ MATRIX 602, a graphene nanotube-formulated super-concentrate based on crosslinking carrier for liquid silicone rubbers (LSR), room temperature vulcanised rubber (RTV) and high consistency rubbers (HCR), was specifically developed to improve nanotube usability by providing a fine dispersion of nanotubes in the host matrix while maintaining softness.

The cost of our SWCNT products depends on the quantity ordered. Please reach out to us for a personalized quote.

Polydimethylsiloxane + zinc chloride (CAS-No. 7646-85-7) + zinc oxide (CAS-No. 1314-13-2)

Application cases

Related video

Graphene nanotubes for elastomers: consistent conductivity with high mechanical performance

Media on graphene nanotubes in massage devices

Graphene Nanotubes in Silicone Power Advances in Medical Electronics

https://www.plasticstoday.com/medical/graphene-nanotubes-in-silicone-power-advances-in-medical-electronics

EU approves silicone incorporating nanotubes for medical devices

https://www.rubbernews.com/news/eu-approves-silicone-rubber-compound-graphene-nanotubesScientific validation

Electrostatic Dissipation in 3D-Printable Silicone

Low loadings (<1 wt %) of TUBALL™ can be sufficiently dispersed into silicone resins that can be 3D printed, and the resulting material shows a significant improvement in electrostatic dissipation through the reduction in electrical resistivity with minimal effect on its mechanical properties.