Powder

coatings

Graphene nanotubes for powder

coatings: electrical conductivity,

durability, and aesthetics

TUBALL™ graphene nanotubes enhance powder coatings by providing stable anti-static properties while preserving the original mechanical properties of the material. Nanotubes enable the creation of colorful, durable coatings with ESD protection, using standard production technology without the need for special adaptations. By adopting graphene nanotube-enhanced electrically conductive powder coatings, manufacturers can overcome the limitations of conventional conductive agents. This results in a cleaner production process with no carbon dust, greater flexibility in final formulations, and improved overall cost-efficiency.

Main properties

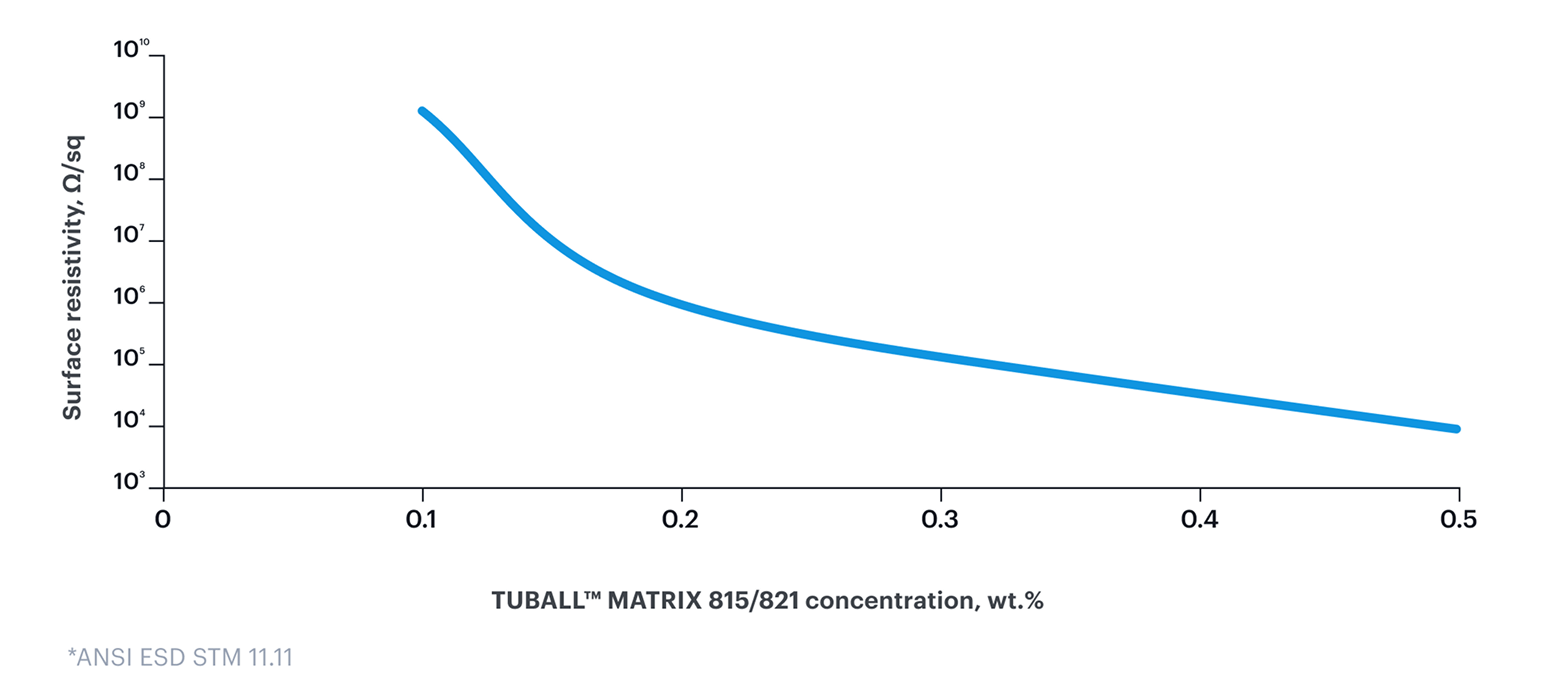

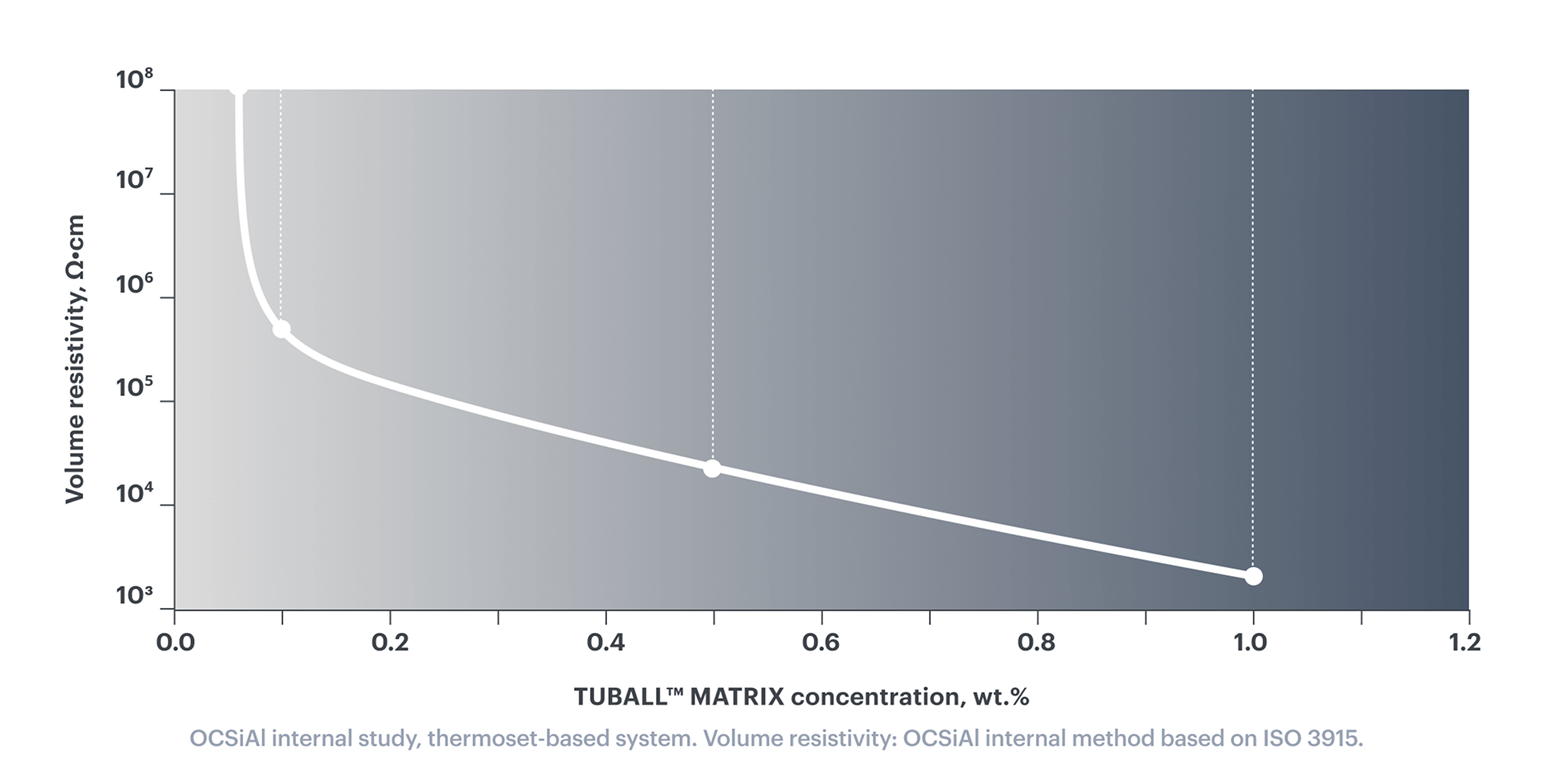

Full range of electrical

resistivity

10⁴–10⁹ Ω/sq

Preserved mechanical

properties

Customizable

coloration

Anti-static powder coatings

What are ESD powder coatings?

Electrostatic dissipative coatings are designed to prevent the buildup of static electricity on surfaces. Compared to liquid coatings, powder coatings can be effectively applied to both vertical and horizontal surfaces. They also offer greater efficiency, enhanced mechanical strength, improved durability, and increased environmental friendliness, as they are practically solvent-free.

ESD powder coatings are widely used in industries where electrostatic discharge can damage sensitive electronic components, such as in electronics manufacturing, cleanrooms, automotive, and aerospace applications.

These ESD coatings must provide a permanent, stable level of electrical conductivity independent of humidity, to safely dissipate static charges and protect equipment and personnel. TUBALL™ graphene nanotubes provide epoxy coatings and polyester coatings with ESD protection while maintaining color and resistance to wear, corrosion, and chemicals. Such ESD powder coatings can be applied via spray, ensuring easy processing and cost-efficiency.

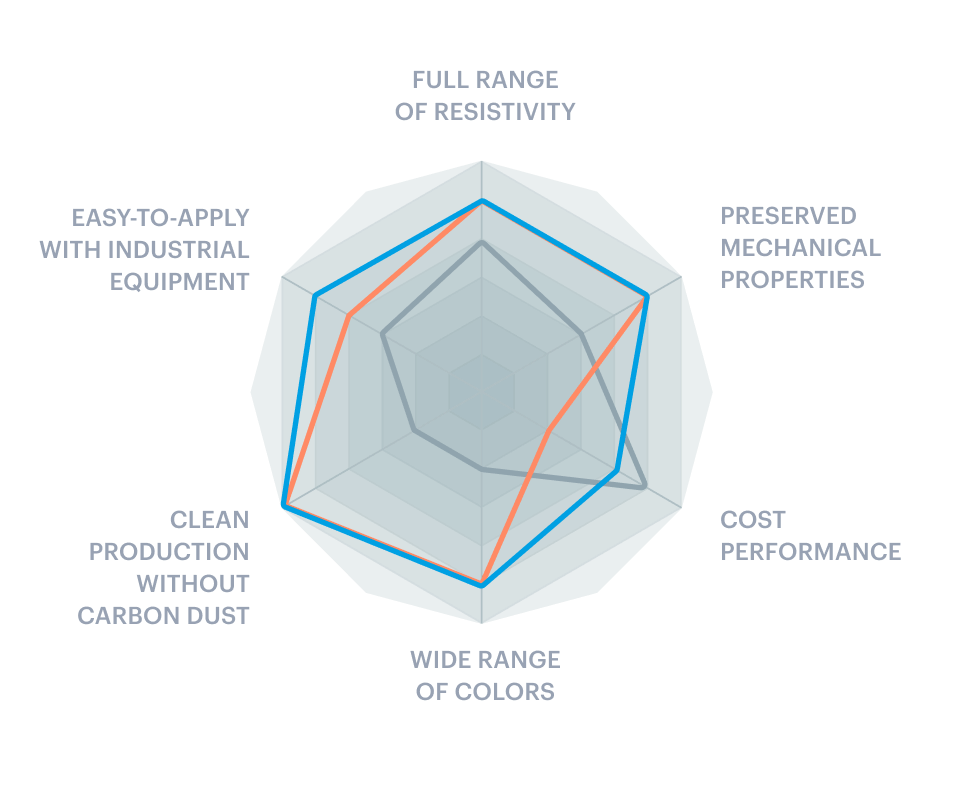

Graphene nanotubes outperform standard additives

Unlike other additives, TUBALL™ graphene nanotubes deliver good performance of all key parameters of textile. Effective at ultralow doses, nanotubes provide anti-static performance without affecting a fabric’s mechanical properties, color, or production processes. Unlike carbon black, they produce no dust and leave no carbon on the surface, while minimally impacting formulation viscosity and density.

- DIAGRAM

- TABLE

- TUBALL™ nanotubes

- Carbon black

- Conductive mica

* This diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

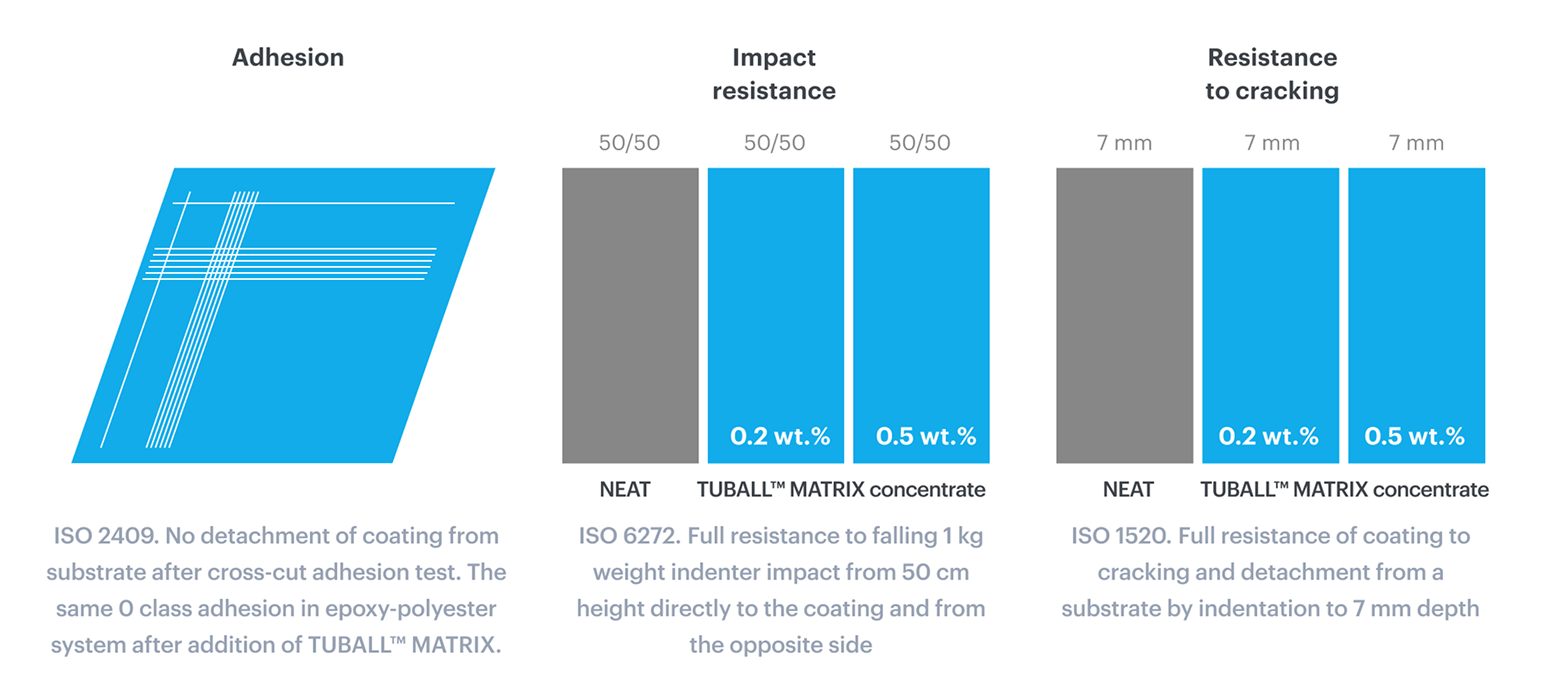

Maintained mechanical performance

In contrast to conventional conductive additives, the ultralow dosage of TUBALL™ nanotubes required and nanotubes’ unique morphology help preserve key mechanical properties such as adhesion, impact resistance, and crack resistance.

Variety of color

The required extremely low dosage of TUBALL™ graphene nanotubes creates the opportunity to produce colorful solutions where desired.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

Additional benefits

Flexibility in

formulation

No influence on

melt viscosity

More efficient

logistics

Industry-friendly forms of nanotubes for standard processing

TUBALL™ MATRIX 821 beta and TUBALL™ MATRIX 815 beta are concentrates based on reactive polymer and pre-dispersed graphene nanotubes. They were specifically designed for various coating systems, including epoxy, polyester, and epoxy-polyester hybrid. Concentrates can be added during the compounding stage and don’t affect standard processing or equipment.

Polyethylene wax

Reaction mass of fatty acids, montan-wax, ethylene esters

Application cases

Related video

Media on graphene nanotubes in powder coatings

Enhancing Powder Coatings with Graphene Nanotubes

https://www.powdercoatedtough.com/News/ID/5388/Enhancing-Powder-Coatings-with-Graphene-Nanotubes

Expanding the freedom of design: powder coating on FRP thanks to conductive gelcoats with graphene nanotubes

https://www.nanotech-now.com/news.cgi?story_id=56585