Silicon

Anodes

TUBALL™ is the industry standard in silicon-based anodes

“Single-walled carbon nanotubes are like magic in electrodes where particles have huge volume change—they turn garbage into gold.”

— Prof. Jeff Dahn, NSERC/Tesla Canada Inc. Industrial Research Chair, one of the world’s leading electrochemists. – March, 2025

We founded the single wall nanotube industry and invented the only scalable synthesis technology delivering a consistently high-quality product validated by customers worldwide. Backed by a global team with unmatched expertise, OCSiAl sets the standard.

Main properties

Makes it possible

to increase silicon content

Significantly

prolongs cycle life

Minimized

swelling

How do SWCNTs work in silicon anodes?

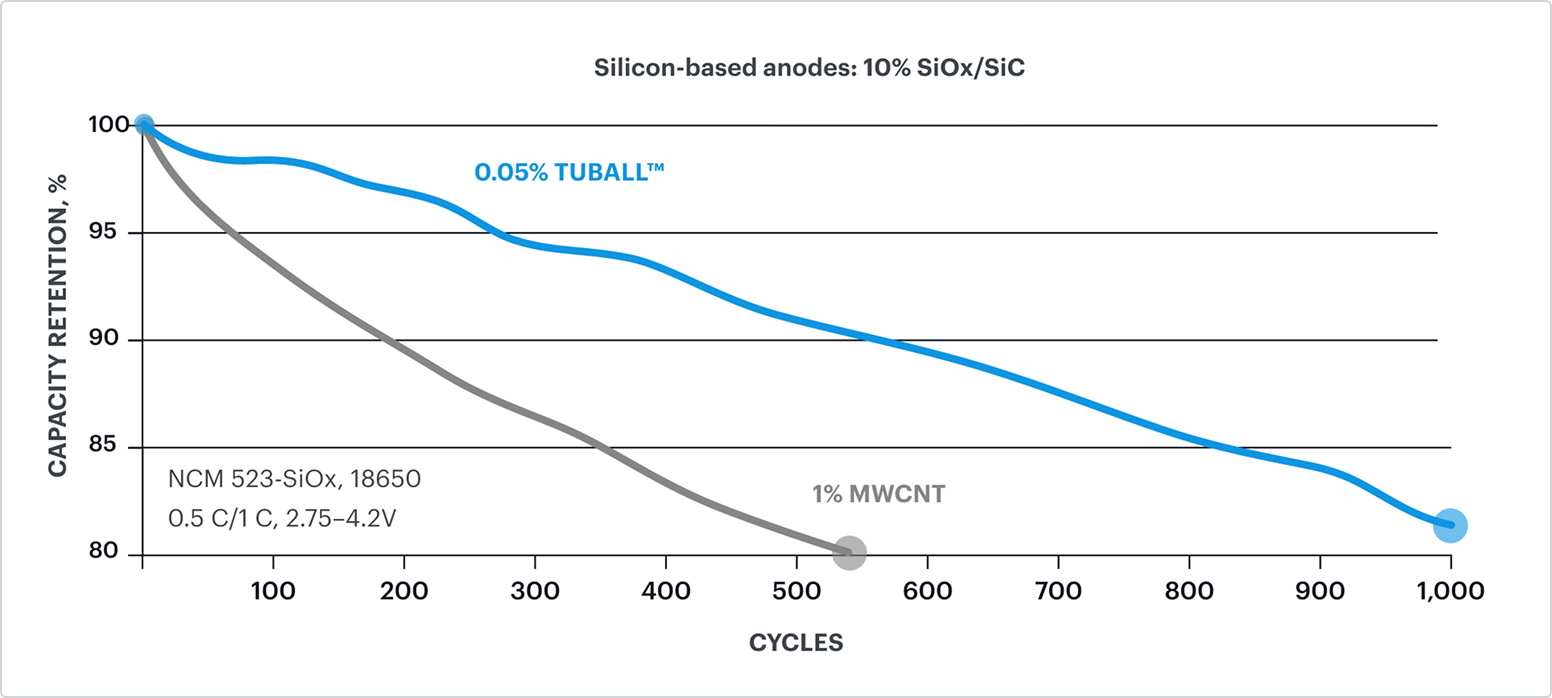

TUBALL™ single wall carbon nanotubes set a new industry benchmark in silicon anode performance. By forming a robust, long-lasting conductive network, TUBALL™ bridges silicon particles and prevents the structural degradation caused by silicon’s natural volume expansion and cracking during cycling.

Longer cycling

of silicon-rich anodes

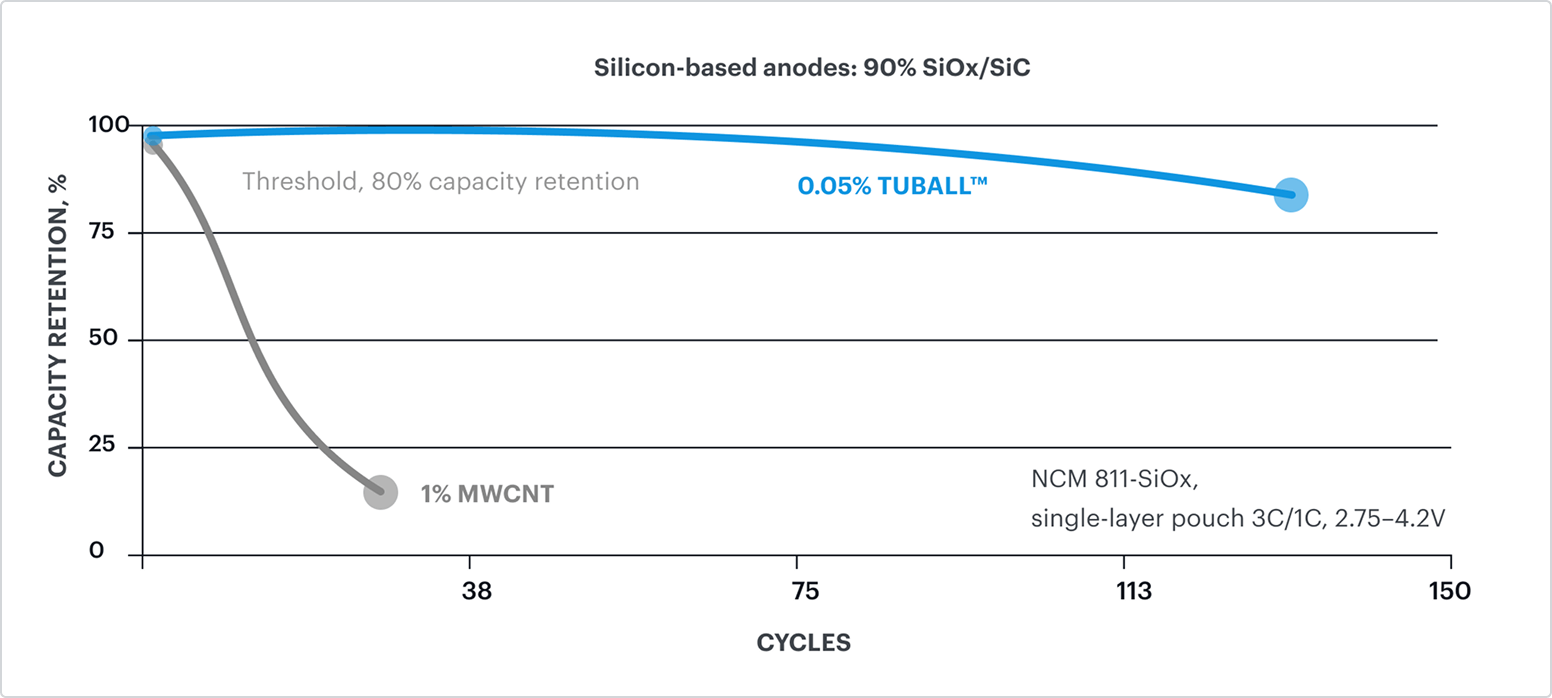

The more silicon in the anode, the more essential becomes the use of single wall carbon nanotubes in the design.

In silicon-rich anodes (up to 90% SiOx/SiC), volume expansion becomes a critical challenge. Without a robust conductive network, silicon particles fracture and rapidly lose capacity.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

Minimized swelling

When using traditional additives like carbon black or MWCNTs, silicon anodes swell by up to 160%, causing the conductive network to break down and leading to rapid performance loss.

With TUBALL™ single wall carbon nanotubes, swelling is reduced to just ~20%. The conductive network remains intact.

Ready to use

solution

TUBALL™ BATT H2O is a plug-and-play solution designed for seamless integration into existing lithium-ion battery production lines. It comes as a stable, water-based concentrate compatible with standard slurry mixing, coating, and drying processes — no special equipment or process changes needed. Battery manufacturers can easily upgrade to high-silicon anodes and achieve energy density targets without disrupting current workflows. This makes it a practical, low-risk path to next-generation battery performance.

Material system: LIB Anodes (SiC, Si/O, graphite)

Concentrate carrier: Water, CMC, other

TUBALL™ BATT H2O is an ultrafine TUBALL™ nanotube dispersion in water for high-energy Si anodes. It creates a robust network inside the Si anode and solves the problem of its degradation, allowing Li-ion battery makers to use record high quantities of silicon in the recipes of their cells for the first time and reach the desired energy density targets, as well as unlocking fast-charging capabilities.

The price of our nanotube products is determined by the quantity. Reach out to us for a personalized offer.

Related video

Media on graphene nanotubes in Silicon anodes

Enhancing Powder Coatings with Graphene Nanotubes

https://www.powdercoatedtough.com/News/ID/5388/Enhancing-Powder-Coatings-with-Graphene-Nanotubes

Expanding the freedom of design: powder coating on FRP thanks to conductive gelcoats with graphene nanotubes

https://www.nanotech-now.com/news.cgi?story_id=56585

Graphene nanotubes provide a shortcut to add conductivity to powder coatings

https://www.coatingsworld.com/issues/2021-10-01/view_breaking-news/graphene-nanotubes-provide-shortcut-to-add-conductivity-to-powder-coatings/Scientific validation

Investigating operating protocols to extend the lifespan of silicon anodes in Li-ion batteries

Silicon anodes containing a small amount of SWCNTs (0.5 wt%) show much better stability when operated at a high state of charge, because in this regime they maintain lower impedance and degrade more slowly. The study reveals that carefully choosing the voltage window and lithiation/delithiation depth — together with the presence of SWCNTs in the electrode — can dramatically extend the cycle life of silicon anodes.

Investigation of Expansion and Potential of Si-dominant Anodes with Binder Modification in Full Cells

They examine how Si–PAA anodes reinforced with a small amount of SWCNTs behave under different voltage windows, focusing on how much the electrode expands and how quickly it degrades. When the silicon is cycled in a milder voltage range—meaning less Si is actually lithiated each cycle—the Si/SWCNT/PAA structure remains far more mechanically stable, leading to over five-fold longer cycle life despite reduced usable capacity.

Unraveling the impact of CNT on electrode expansion in silicon-based lithium-ion batteries

CNTs mechanically restrain silicon, slow crack growth, and suppress excessive SEI buildup, which dramatically reduces electrode swelling even under high-density, industrial conditions. Because CNTs maintain electrical pathways and prevent particle pulverization far better than carbon black, Si–graphite anodes with CNTs deliver much stronger cycling stability, improved fast-charge performance, and superior low-temperature behavior in full 1 Ah pouch cells.

Characterizing Structure and Electrochemical Properties of Advanced Si/C Anode Materials

This paper dissects commercial Si/C composites where sub-nanometer silicon clusters are tightly confined inside a highly microporous carbon matrix, delivering ~2000 mAh g⁻¹ with graphite-like tap density (~1 g cm⁻³) and far less stack swelling than you’d expect from 300% Si expansion. By combining detailed nanostructural analysis (Debye XRD, TEM, BET) with operando stack-pressure measurements in pouch cells, it shows how this confinement suppresses cracking and irreversible stack growth, making high-Si anodes behave like something you could actually commercialize.

Optimization of Si-containing and SiO based Anodes with Single-Walled Carbon Nanotubes for High Energy Density Applications

SWCNTs keep Si and SiO particles electrically connected as they expand and contract, preventing isolation and early capacity loss. Even tiny amounts of nanotubes strengthen the electrode enough that simple CMC/SBR binders work well, and high-loading Si/graphite composites cycle far more stably. Their mechanical flexibility and long, web-like structure make SWCNTs the key element that stabilizes these high-energy anodes.

Investigation of The Failure Mechanisms of Li-Ion Pouch Cells with Si/Graphite Composite Negative Electrodes and Single Wall Carbon Nanotube Conducting Additive

SWCNTs act as the electrical “glue” that keeps Si/graphite composite anodes connected even as the silicon repeatedly expands and contracts. In these pouch-cell tests, the nanotubes prevent active-mass loss and keep the anode structurally coherent, so the main failure mode is no longer particle isolation—but steady lithium loss into a continually growing SEI. In other words, SWCNTs successfully stabilize the electrode; the remaining degradation comes from electrolyte-driven SEI growth, not from the anode falling apart.