Protective

wear

Graphene nanotubes for workwear: ESD safety and standard compliance

Anti-static clothes empowered by graphene nanotubes ensure compliance with ATEX zone regulations and protect workers from the risk of sudden electrostatic discharge (ESD), high temperatures, sparks, and splashes of molten metal. Thanks to their unique structure, and additionally to their exceptional conductive properties, graphene nanotubes maintain the fabric’s original strength and comfort, providing an option for breathability and flame resistance, while guaranteeing no carbon dust on the surface, no changes to manufacturing processes, and no limitations in color or design, in contrast to other anti-static additives. These benefits make graphene nanotubes a superior alternative to carbon black, liquid conductive agents, and conductive yarns—raising the bar for anti-static protective clothing in high-risk environments.

Main properties

Permanent electrical

resistance

<10³–10¹¹ Ω

Preserved mechanical

properties

Compliance with

industrial safety

standards

Colorful aesthetic

appeal

Anti-static workwear for increased safety

What is ESD safe workwear?

In many industries, static electricity is a serious hazard. Friction-generated sparks can ignite flammable substances, damage electronics, and injure workers. ESD-sensitive environments—such as electronics manufacturing and ATEX zones—require anti-static protective workwear. Conductive clothing helps safely dissipate static charge. Anti-static textiles reduce fire and explosion risks, protect equipment, and improve the safety and comfort of workers.

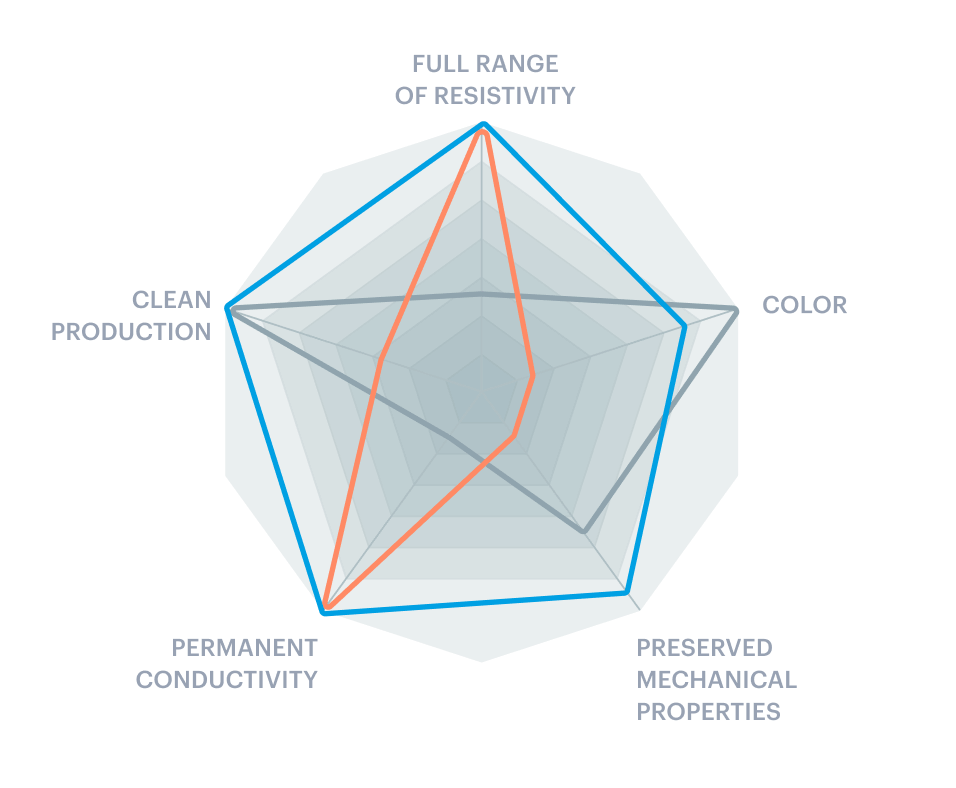

Good all-around performance

Unlike other additives, TUBALL™ graphene nanotubes deliver good performance of all key parameters of textile. Effective at ultralow doses, nanotubes provide anti-static performance without affecting a fabric’s mechanical properties, color, or production processes. Unlike carbon black, they produce no dust and leave no carbon on the surface, while minimally impacting formulation viscosity and density.

- DIAGRAM

- TABLE

- TUBALL™ nanotubes

- Carbon black

- Ammonium salts

* This diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

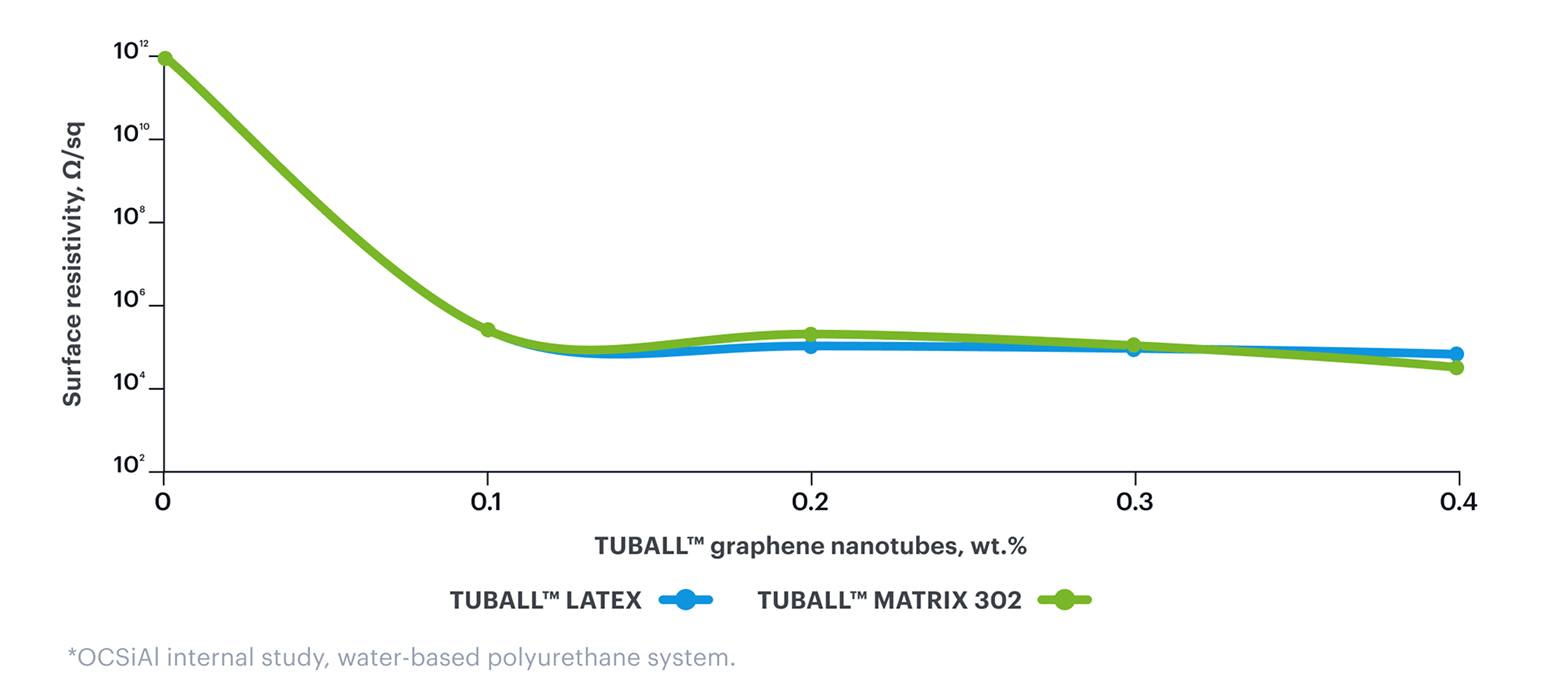

Wide range of electrical conductivity

TUBALL™ nanotubes enable a full range of electrical resistance—from anti-static to conductive—making them suitable for various textile types and applications. This ensures reliable ESD protection for safety wear and compliance with standards requiring resistance values typically between 10³ and 10¹¹ Ω.

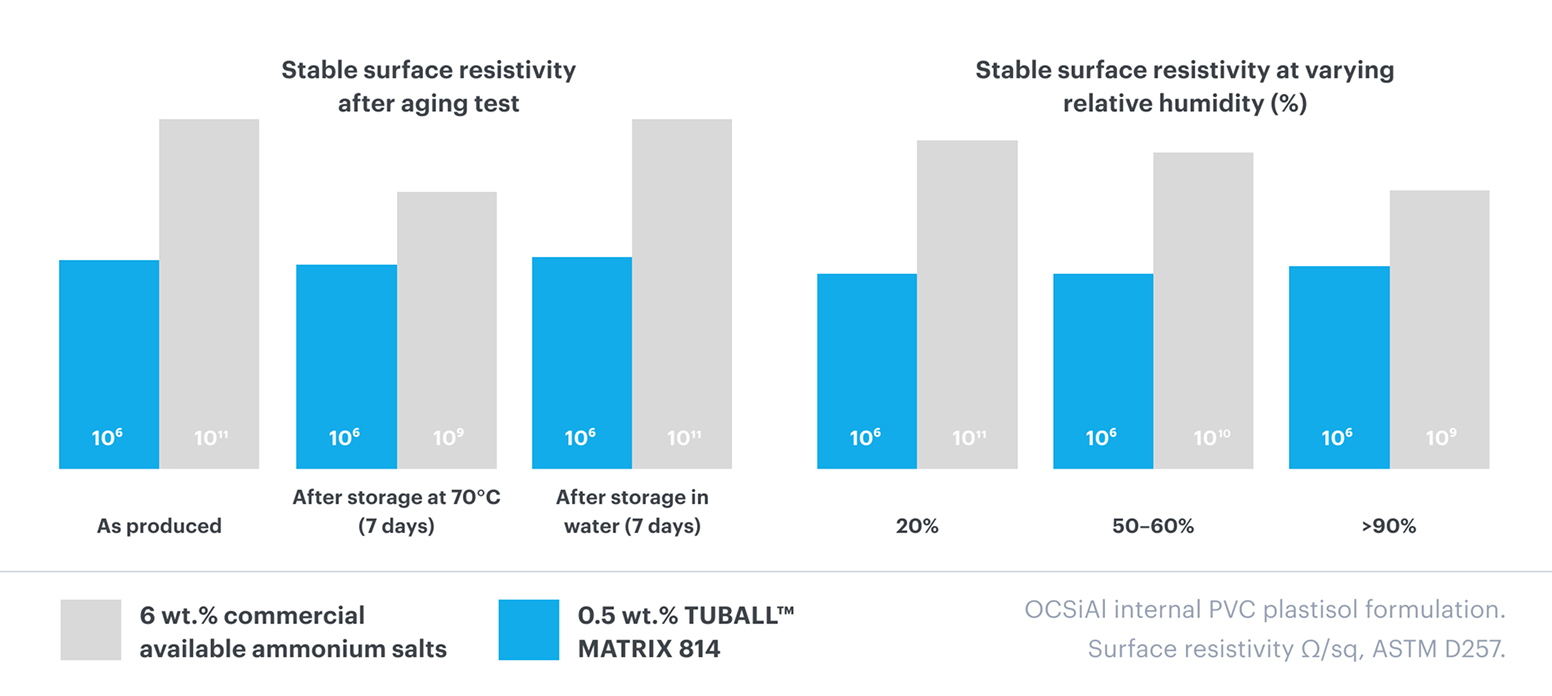

Stable anti-static properties over time

The consistent conductive performance provided by TUBALL™ nanotubes remains stable over time and is unaffected by humidity or aging.

Compliance with safety regulations

TUBALL™ graphene nanotubes make it easy to meet all major industrial standards for ESD protection in safety wear, including EN ISO 18080, EN ISO 20345, ASTM F1506, ANSI/ESD STM2.1, EN 61340, EN 16350, ATEX Directive 95/2014, and others, which are used in critical sectors such as oil and gas, chemical processing, pharmaceuticals, electronics manufacturing, healthcare, and automotive.

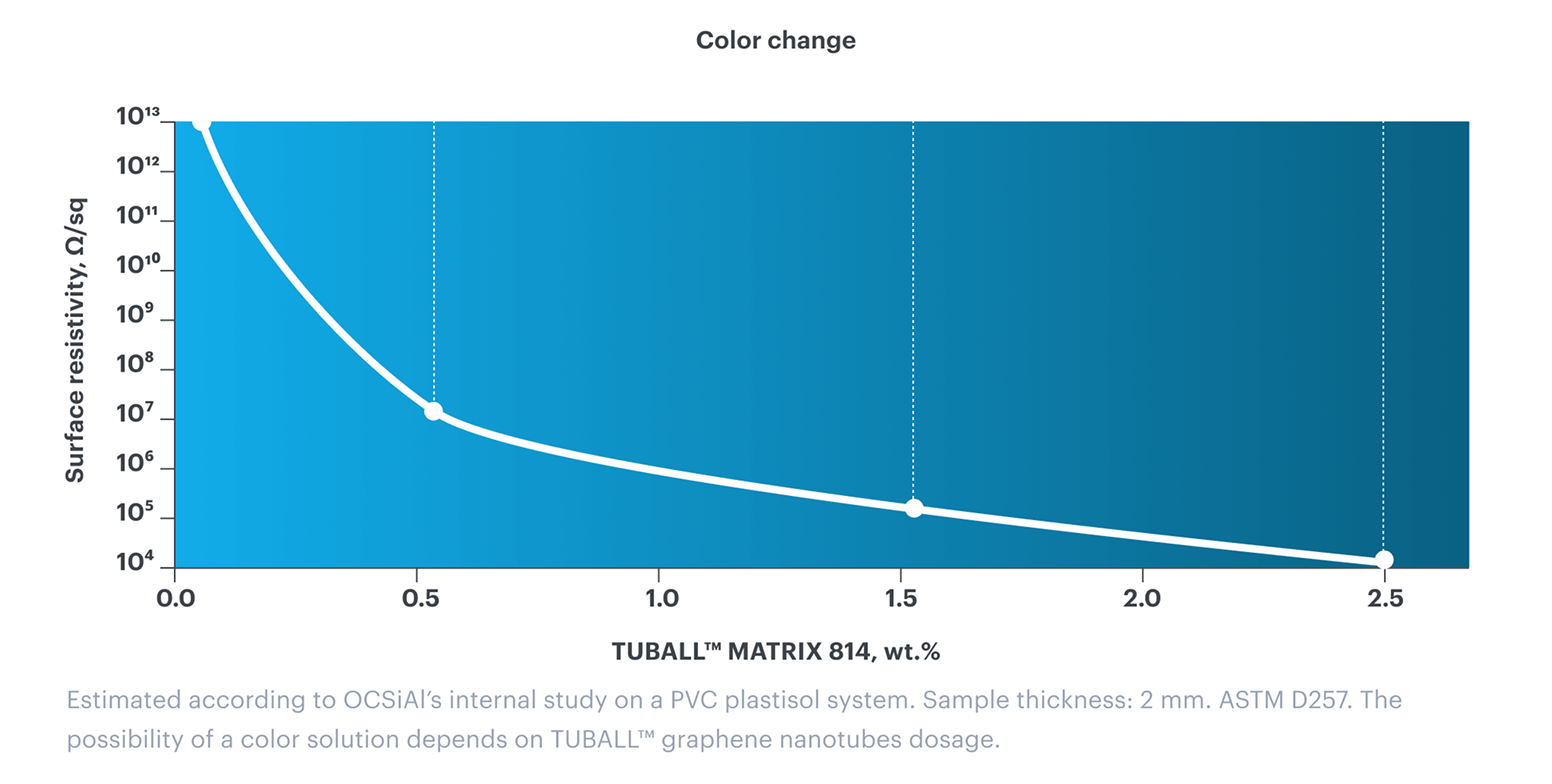

Preserved variety of colors

The required extremely low dosage of TUBALL™ graphene nanotubes creates the opportunity to produce colorful solutions where desired.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

Additional benefits

No carbon contamination on material surface

Limited influence on rheology

Dust-free production

Standard processing

The use of TUBALL™ graphene nanotubes in the form of concentrates and suspensions streamlines nanotube handling at standard PPE production facilities, enabling clean and efficient processes. These solutions are specifically designed for a wide range of systems—including solvent-free and solvent-based polyurethane, acrylic, silicone rubber, PVC plastisol, and latex—and can be easily integrated into standard production processes at the mixing or compounding stages.

Agente antiestático para compuestos de látex de color: solución de fácil uso, que garantiza el cumplimiento de las normas de protección contra la acumulación de carga estática

Aditivo conductivo a base de un surfactante con tensioactivo para resinas fenólicas, PU de base acuosa y revestimientos acrílicos sin afectación en el color y las propiedades mecánicas. Se utiliza ampliamente para aplicaciones acrílicas a base de agua.

Agente conductor no reticulado para siliconas líquidas, que no causa impacto negativo en el color, la viscosidad y la durabilidad del material

Agente conductor reticulado para siliconas líquidas, que no causa impacto negativo en el color, la viscosidad y la durabilidad del material

Este concentrado de nanotubos de grafeno TUBALL™ está destinado a proporcionar la conductividad eléctrica estable y permanente al plastisol a base de policloruro de vinilo. Se pueden proporcionar a los compuestos de PVC plastisoles desde características antiestáticas hasta conductivas.

Esto aporta ventajas adicionales en comparación con aditivos tradicionales:

- A diferencia del carbon black, que se usa en dosis altas, TUBALL™ MATRIX garantiza la conductividad, manteniendo las propiedades mecánicas y las oportunidades de color

- Proporciona las propiedades conductivas estables y permanentes, comparables con agentes antiestáticos orgánicos

Application cases

Related video

How to achieve a new level of safety in mining?

Media on graphene nanotubes in protective wear

OCSiAl Opens First European Graphene Nanotube Production Facility To Drive Advanced Textiles And PPE

https://www.textileworld.com/textile-world/nonwovens-technical-textiles/2024/10/ocsial-opens-first-european-graphene-nanotube-production-facility-to-drive-advanced-textiles-and-ppe/

OCSiAl: Graphene nanotubes expand textiles’ functionality

https://textination.de/en/news/entry/ocsial-graphene-nanotubes-expand-textiles-functionality