Protective

films

Graphene nanotubes for anti-static films: safety & touch-screen operation

In the consumer electronics and semiconductor industries, protective films serve a dual role: they protect smartphones, tablets, and laptops from scratches, fingerprints, and dust, while also providing durable ESD protection for semiconductor devices and other static-sensitive components during manufacturing, handling, transportation, and storage. These films can also be used for electronics and wafer handling for ESD-safe contact surfaces in positioning and sensing applications.

By incorporating graphene nanotubes, protective films achieve stable, permanent piezoresistive response, combining strong mechanical performance, high functionality, and minimum impact to film and its production process. Nanotubes enable transparent, anti-static coatings for 3C products and wafer storage without requiring changes to standard processing methods or equipment.

Main properties

Stable electrical

resistivity

Up to 80%

transparency &

<6% haze value

Touch-screen

performance &

anti-dust effect

Preserved peel-off

strength and wet-out

performance

Anti-static protective film for electronics

What is PSA film?

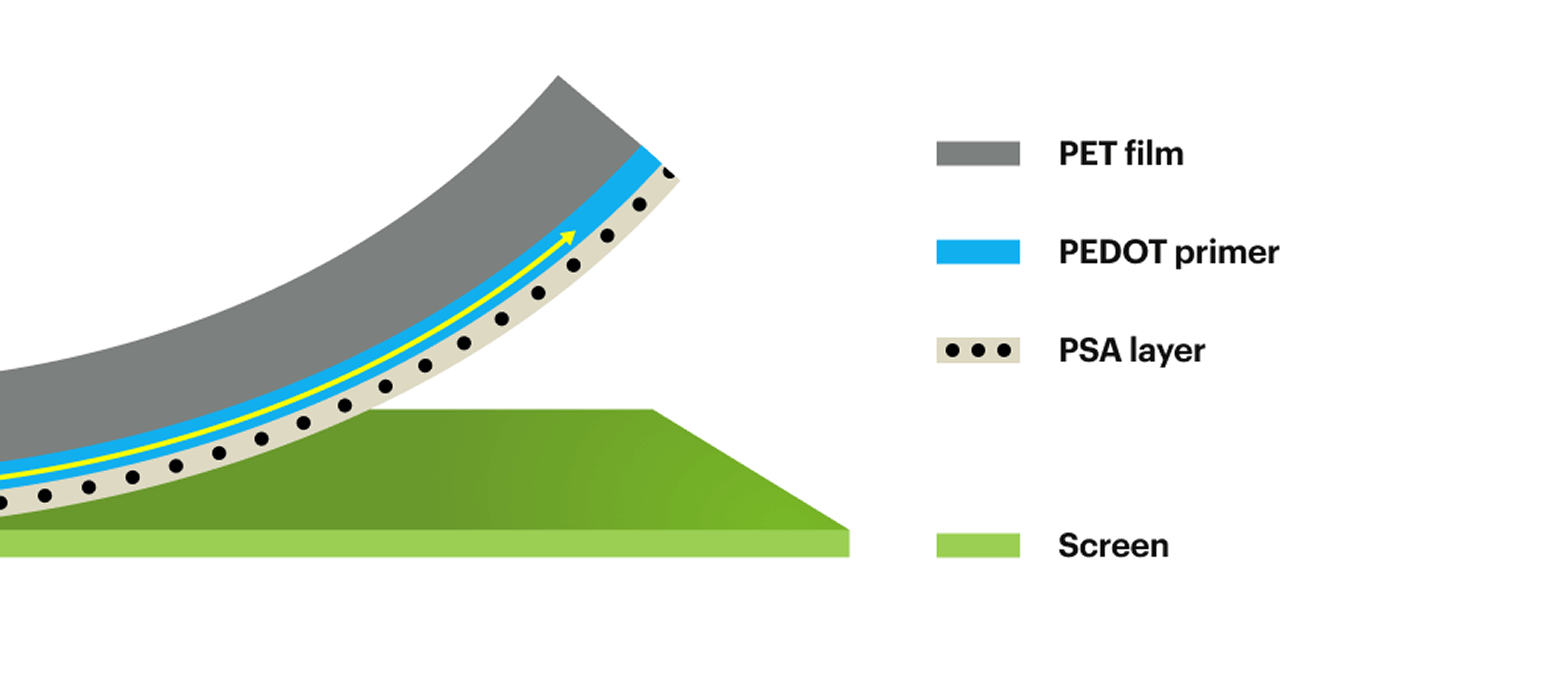

Pressure-sensitive adhesive film used in the computer, communications, semiconductors, and consumer electronics industries adheres to surfaces with light pressure, providing excellent permanent piezoresistive response and protection against scratches, dust, and fingerprints. Their applications are diverse and essential for protecting wafers as an engineered substrates that solve critical challenges in wafer thinning, dicing, 3D integration, and protection, directly impacting manufacturing yield and device reliability.

The anti-static properties of this film are crucial for preventing the build-up of static electricity on electronic components and devices, protecting them from ESD-caused damage and dust collection. For this reason, the PSA layer should be electrically conductive.

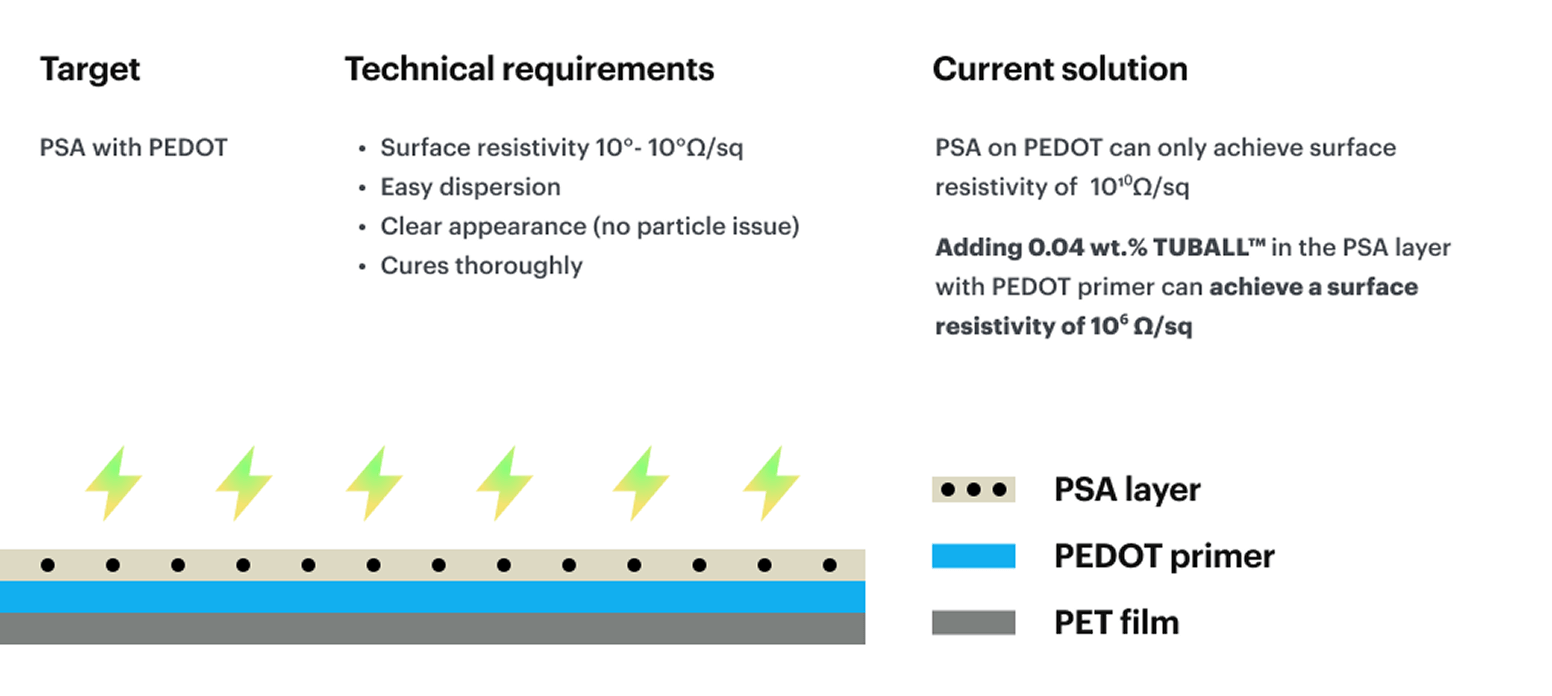

Graphene nanotubes ensure film meets industry requirements

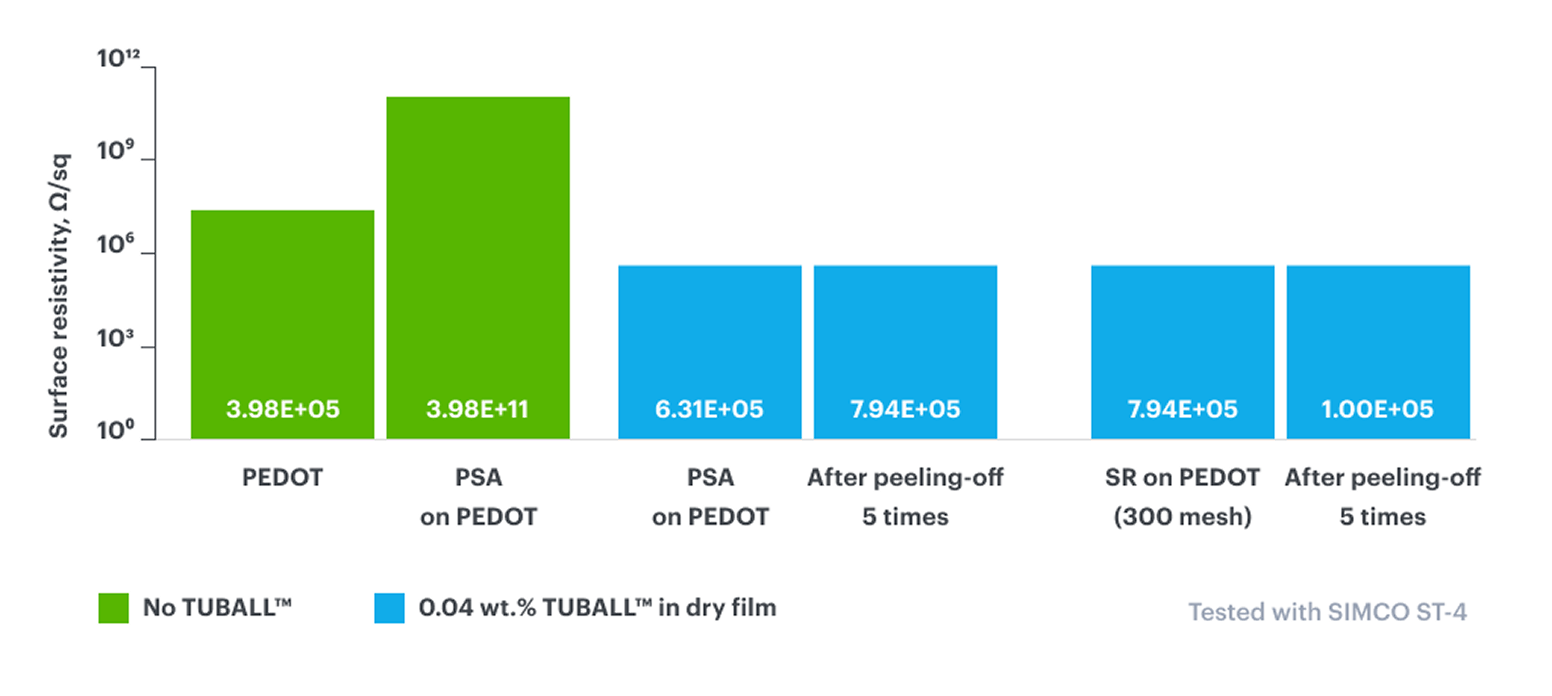

With an extremely high length-to-diameter ratio and a large surface area, coupled with excellent conductive and thermal properties and high strength, the addition of just 0.04 wt.% graphene nanotubes inside of the films on PET or PTFE substrates guarantees stable, permanent electrical resistance of 10⁶ ohms within the pressure-sensitive adhesive layer.

Such an ultralow dosage has no influence on the key mechanical parameters of the material, making nanotubes a superior conductive agent for 3C protective films, semiconductor devices, electronic components, and other static-sensitive products. In comparison, traditional PSA on conventional polymer primer can only achieve a surface resistivity of 10¹⁰ ohms/sq, and at lower resistivity levels, it tends to become unstable over time.

Permanent, uniform electrical conductivity

Graphene nanotubes create a permanent 3D conductive network within the material, which remains stable throughout its service life. Their ultra-long morphology ensures no degradation of anti-static properties in film coatings.

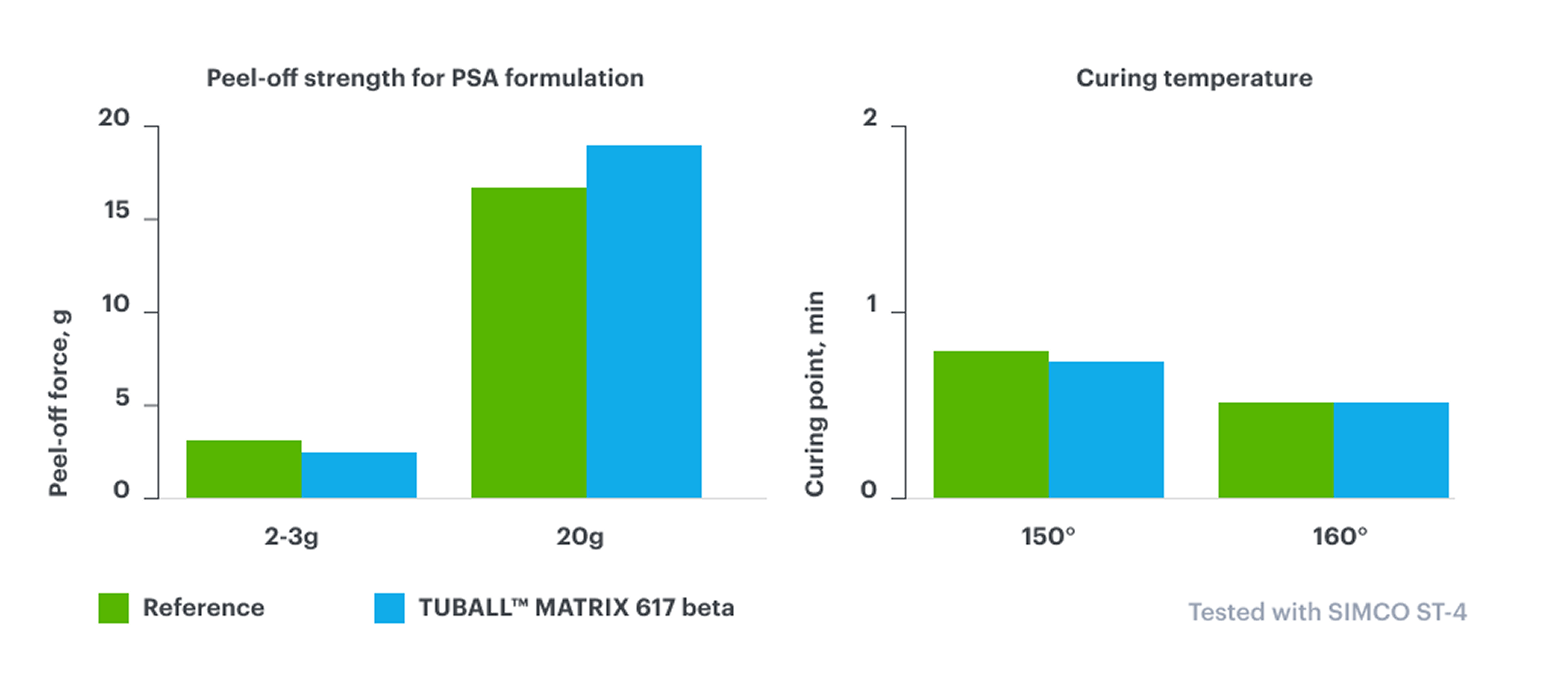

Maintained technical performance

Using graphene nanotubes in combination with PEDOT primer makes it possible to get even lower surface resistivity and to maintain all key technical parameters, including peel-off strength, with the original curing system, up to 80% transparency, less than 6% haze value, and good wet-out performance.

Touch-screen performance and anti-dust effect

The electrical resistivity provided by TUBALL™ graphene nanotubes enables the anti-dust effect and touch-screen performance of the film, ensuring the required functionality and simplifying device maintenance.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

Additional benefits

Can be applied without primer

No oil migration to the surface

Carrier compatible with various silicone PSA resins

Industry-friendly forms of nanotubes allow standard processing

TUBALL™ based concentrate and suspensions are specifically designed for silicone PSA systems and water-based systems to provide compatibility with standard mixing process and equipment. The concentrates are easy to handle even in demanding applications, notably in low solid-content systems. It can be added during the slurry compounding stage and doesn’t affect the manufacturing process.

TUBALL™

MATRIX 617 beta

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX 617 beta

Suspensión única de nanotubos de grafeno

Dimethyl, methylvinyl siloxane

Application cases

Related video

Electrical resistivity guide: measurement, standards & troubleshooting

Media on graphene nanotubes in protective films

OCSiAl makes a breakthrough in the 3C field: graphene nanotubes have both conductivity and transparency

https://www.echemi.com/cms/1891428.html

Graphene nanotubes revolutionize protective film technology: ultrathin, permanently conductive PSA

https://ocsial.com/news/graphene-nanotubes-revolutionize-protective-film-technology-ultrathin-permanently-conductive-psa/